As overhead and bridge cranes become increasingly used in commercial, industrial and shipping applications throughout the world, crane safety has become an important concern for both workers and business owners. There are many different ways in which crane safety can be improved, both by proper operating procedures and also through the use of new technologies, such as LED crane lights designed to increase situational awareness in areas where cranes operate. Combined together, these techniques can not only improve the safety of overhead cranes but also the efficiency of the overall operations due to reduced down time from accidents.

Key Crane Safety Methods

As mentioned previously, there are multiple ways in which crane safety can be improved. The first of these is through the implementation of proper safety protocols and procedures. The most important of these is the inspections of various pieces of equipment such as the control pennant, load hooks, safety latches and load bearing ropes or cables. Other items to be inspected include ladders, platforms and walkways. The purpose of these inspection points is to ensure that equipment is properly setup, installed and has no defects or malfunctions.

In addition to safety inspection checks, another important aspect of crane safety is safe operational procedures when the crane is actually in use. This comes down to several factors, the main one being the assurance that personnel are not in the area in which the crane is operating. However, this is easier said than done, as crane operators may clear an area only to have coworkers step under or around the load being moved after operations commence. The use of spotters on the ground can help avoid this situation by warning other personnel of active crane operations and preventing individuals from entering the area.

In addition to these safety inspections and procedures, the use of both legacy and newly available technologies has proven to be a tremendous assistance in improving overhead and gantry crane safety. One of the simplest ways to accomplish this is by the use of audible warnings that sound when the crane starts and/or is in operation. In addition to this, proximity sensors can be installed for the purposes of monitoring an area in which cranes are operating. If personnel come into these areas with active operations, these sensors can work in conjunction with the warning system to alert the operators and other personnel of the dangers.

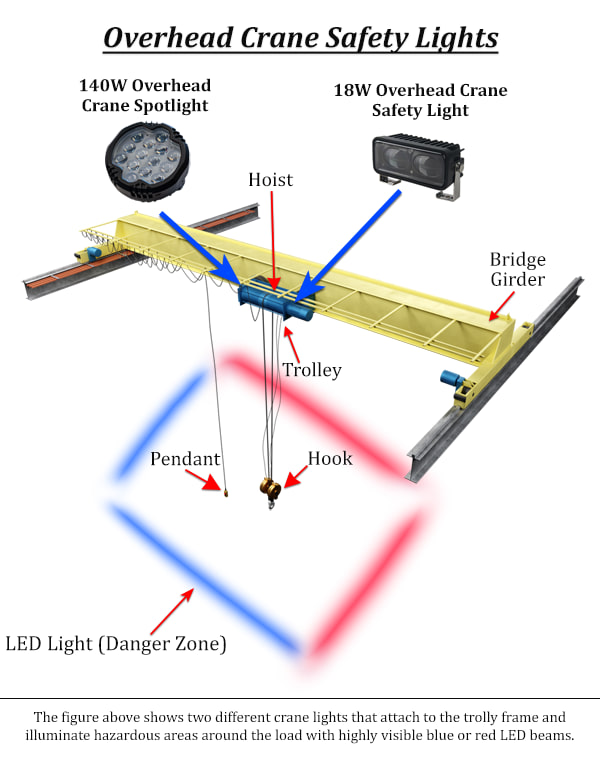

By far the most effective way in which technology can work to improve safety is by the use of crane lights. Over the past decade, LED technology has improved dramatically in longevity, durability and lumen output. These improvements have made the use of crane safety lighting possible, with powerful lighting output providing a clear warning on the floor around the crane head and the load it is carrying. Crane warning lights provide crisp boundaries that are impossible to ignore, ensuring all personnel in the area are aware that a crane is engaged in operations overhead.