Hazardous Storage Lighting

LED Hazardous Storage Lighting

Hazardous chemicals and materials storage is a fact of life in modern day manufacturing and industrial processes. Like any other storage facility, these facilities require significant lighting in order to provide adequate illumination and ensure worker safety. However, unlike most of these areas, hazardous storage facilities have unique lighting requirements to ensure there is no possibility of accidental ignition. For this application, explosion proof lighting fixtures are required in order to ensure that all electrical components are shielded from any outside combustible dust, aerosol or other material that might spark an explosion or fire.

Explosion Proof High Bays

Use inside the facility for ceilings typically around 15 feet or higher

Browse Selection

Explosion Proof Flood Lights

Use either outside the facility or for certain indoor applications. Mount on walls, ceilings, or poles

Browse Selection

Explosion Proof Linear Lights

Suspended ceiling lights for ceilings typically under 15-20 feet high

Browse Selection

Jelly Jar Lights

Specialized light bulbs encased in a metal cage to ensure shatterproof resistance

Browse Selection

Explosion Proof Vapor Tight Lights

Linear fixtures with an extra layer of protection against water vapor

Browse Selection

Hazardous Storage Lighting Information

Any facilities storing explosive materials, flammable compressed gasses or other flammable substances require substantial shielding of any potential ignition sources in order to prevent accidents and ensure a safe working environment. This is especially important in hazardous storage facilities that house an exceptionally large quantity of combustible material. Additionally, this material often sits for months if not years at a time, increasing the risk of a leak going undetected. As a result of this, light fixtures used to illuminate these facilities must be designed to meet specific explosion proof requirements.

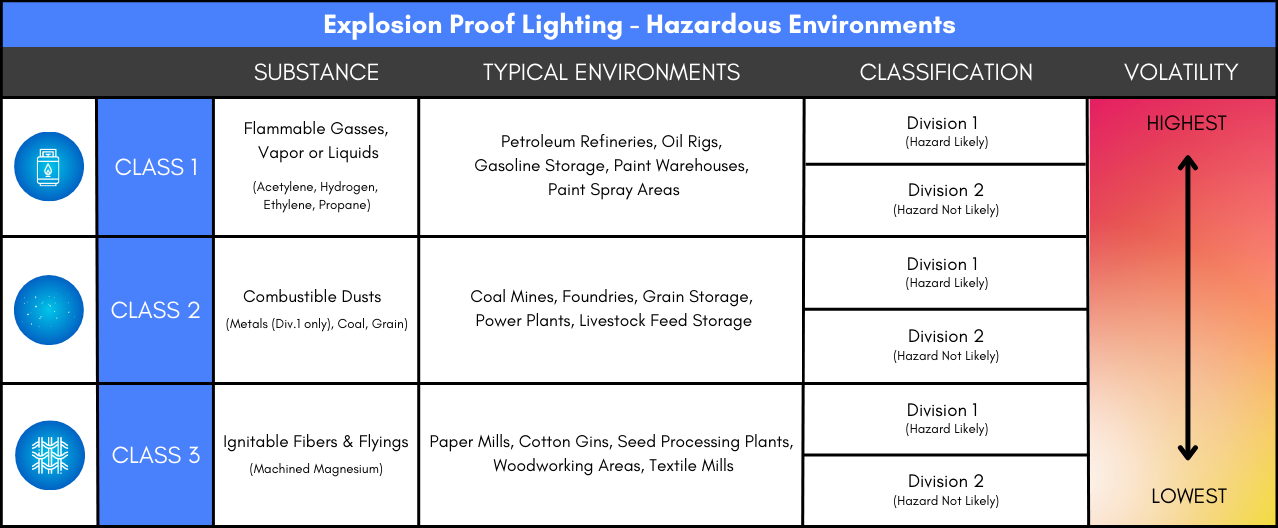

These requirements include being designed and certified to meet explosion proof standards under UL 844. Explosion proof lighting is divided into two different divisions depending on the environment it is used in.

Class 1, Division 1 - These are environments where flammable gas or vapors are present in the atmosphere as part of normal daily operations. This could include sections of a building where containers or materials are routinely checked or filled.

Class 1, Division 2 - These are environments where flammable gasses or vapors are confined within containers or sealed systems during normal operations with a possibility of being leaked into the atmosphere under abnormal operating conditions. This could include static storage sections of a building where a container may unintentionally leak.

Explosion proof fixtures are designed to completely seal any electrical or heat generating components from exposure to any combustible gasses, vapors, combustible dusts or corrosive chemicals that are commonly used in heavy industry. In addition to this, heat considerations must be taken into account when designing these fixtures, and all sparks or flames from lighting are completely sealed and contained within the fixture.

Every hazardous storage facility has a temperature that if exceeded will cause spontaneous ignition of any flammable or combustible material being stored. Known as the “T” rating, this temperature is a critical factor in determining safety standards. It is critical that all lighting fixtures used in hazardous storage applications run cooler than the T rating of the surrounding area.

Hazardous Area Lighting Fixtures

There are multiple types of explosion proof lights that can be used in hazardous storage facilities. Because not every area in the facility has the same lighting requirements, the light chosen will depend on the specific area it is to be used in. Certain areas will require lights with a broad beam pattern to cover a wide area, others will require a narrower more powerful beam in order to project light from high ceilings.

Jelly Jar Lights - Explosion proof jelly jar lights are round lighting fixtures that have impact protection provided by a shatterproof metal caging. These are perfect for providing solid illumination from close proximity areas such as walls or low ceilings.

Explosion Proof Linear Lights - Designed specifically for areas with low to medium ceiling heights, these linear fixtures are perfect for applications requiring explosion proof lighting.

Explosion Proof High Bays - Intended for medium to high ceiling heights, explosion proof high bay lighting fixtures are perfect for casting strong illumination from a mounting height of 15 to 40 feet.

Explosion Proof Vapor Tight Lights - In addition to being explosion proof, these lights are also vapor tight and intended for areas that will see considerable moisture. They can be mounted on poles or simply affixed to the underside of outdoor ceilings and overhangs, such as those found in stairwells, parking structures or entryway canopies.