Mine Lighting

LED Lights for Mining

Coal mines are some of the most dangerous and accident prone work areas in the world, with countless accidents and fatalities every year. Because of the inherently dark conditions and use of heavy equipment within, proper illumination is key for increasing light levels and visibility in order to prevent safety incidents.

We offer top quality LED lighting for mining applications. These lights are certified against dust, water vapor, and Class 1 Division 2 certified for areas within the mine that require explosion proof shielding.

Jelly Jar Lights

Highly versatile lights for that mount to any flat surface inside or outside the mine

Explosion Proof LED Strip Lights

Explosion proof linear shaped lights for high quality illumination from ceilings, walls, or poles

Explosion Proof Vapor Tight Lights

Class 1 Division 2 Linear lights with extra protection against liquids and flammable particles

Explosion Proof Lights

Class 1 Division 1 and Division 2 lights for hazardous locations in the mining operation

LED Sign Projector

Casts highly visible LED warning signs such as stop signs, caution signs, and any other desired signage.

LED Crane Lights

Intended for use on overhead cranes such as those loading and unloading train and freight cars

Shop Now

Shop Now

Mine Lighting Information

Mines many different areas that require specific types of illumination in order to provide proper lighting coverage. Federal law stipulates different lumen ratings for various conditions, with a specific measurement process for the underground sections of mines. This is important in order to ensure optimum visibility for workers, ensuring safety and efficiency.

The largest areas of a mine that need to be illuminated are not the mine shafts themselves, but instead the supporting areas such as loading zones, maintenance bays, parking areas, and more. The efficient functioning of these areas is important in order to support the actual mining operations, with lighting being a critical factor.

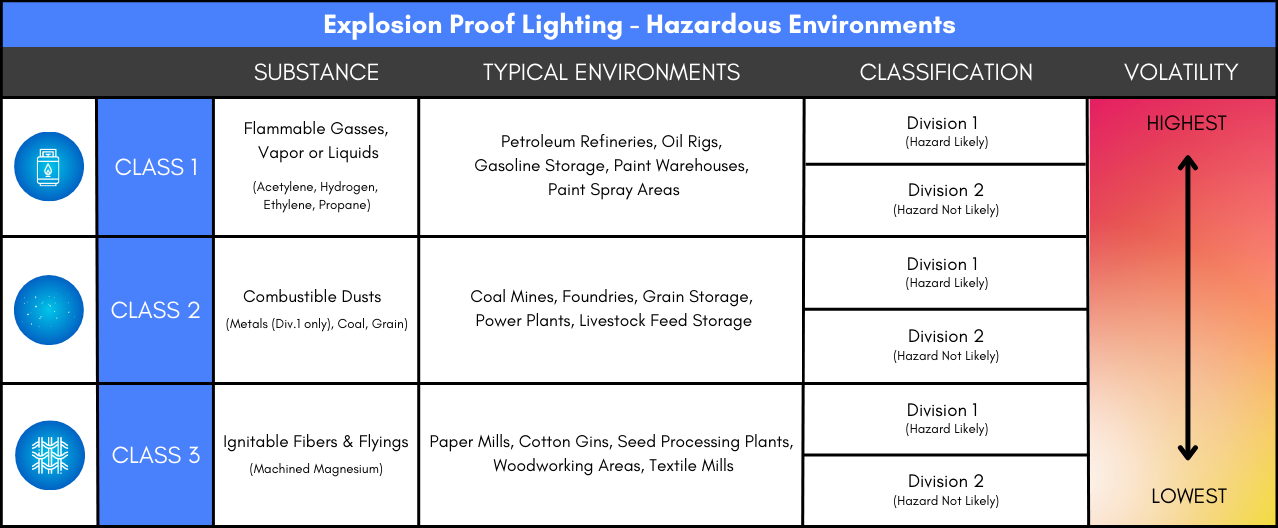

Certain areas that are exposed to explosive gasses, dusts or vapors require explosion proof lighting in order to prevent accidental combustion. These fixtures are sealed from the outside environment, shielding the electronic components from creating any potential source of ignition. They are commonly chosen for areas such as mine shafts and coal processing areas due to the amount of potentially combustible material being handled.

Other areas without the risk associated with combustible materials such as outdoor loading areas, zones with heavy equipment, and parking areas have the ability to use different types of fixtures such as flood lights and wall packs to provide general area lighting. Some of these loading areas utilize large overhead cranes for lifting equipment and materials, which often are equipped with crane safety lights for creating a safety exclusion zone on the ground below.

Thankfully, over the past decade there have been massive advancements in safety lighting technologies, specifically involving LEDs. There are many advantages to this technology, especially in terms of maintenance, longevity and performance. It is for this reason that LED technology has taken over as the go-to selection for the mining industry as a whole.

Mine Lighting by Area

Mine Warehouses - Most mining operations have warehouses and other industrial facilities that are used for storage or machine work. We offer various warehouse lighting solutions that differ based on factors such as ceiling height, building dimensions, activity, temperature, and other environmental factors. These solutions include high and low bay lighting fixtures as well as explosion proof fixtures that are specially designed to withstand harsh environments exposed to water, dust, or combustible particles/fibers.

Mine Workshops - Labor and machine work are common in mining operations. As a result, it’s paramount to ensure these workshop areas have adequate illumination for workplace safety and convenience. We offer a wide variety of shop lighting solutions that are designed to withstand the harsh nature surrounding industrial work.

Fuel Bay - Having a safe and efficient fuel bay that’s in close proximity to work areas is critical in order to keep a mining station operational. As a result, it’s important to ensure that the fuel bay is properly illuminated with fixtures that are designed to operate next to harsh chemicals and combustible fibers. We carry a variety of Class 1 Division 1 and Class 1 Division 2 fixtures such as jelly jar lights that are designed to operate smoothly within this environment.

Interior Mine Lighting - We carry a wide variety of high bay and low bay lighting solutions that are designed to cast illumination from ceilings and walls inside the mining facility. This includes hazardous area lighting solutions that are protected against combustible particles.

Exterior Mine Lighting - We carry a wide variety of LED wall packs and LED flood lights for exterior mine lighting. These outdoor lighting fixtures are designed to be mounted on top of or on the side of buildings and cast illumination to various areas with vehicle and foot traffic. Our exterior lights provide general illumination, security, and safety throughout a mining operation.

Turnstiles & Main Gates - The main entrance of mining operations often have significant foot and vehicle traffic. As a result, it’s important that these areas are well-lit for pedestrian safety as well as convenience.

Parameter Lighting - Having high quality illumination around the parameter of a mining operation is important for security. We use LED area lights and security flood lights that are designed to properly illuminate the exterior of a facility. Our lighting experts help design outdoor lighting plans for our customers to ensure you have adequate lighting spread around the operation.

Admin Area - The main operation area of the mine generally consists of offices and computers. We have top quality LED tubes and office lighting fixtures that are designed to provide a low profile and pleasant illumination throughout office spaces.

Lighting Requirements for Mining

As a part of their safety initiative, OSHA developed standards to make sure that all commercial and industrial workplaces have lighting that is adequate and effective, without having a glare or being excessively bright. Here are relevant lining requirements for mining operations.

| Mine Lighting | Footcandles |

|---|---|

| Warehouse Lighting Requirements | 5 fc |

| Emergency Lighting Requirements | 5 fc |

| Lighting for Temporary Construction | 5 fc |

| Manufacturing Lighting Requirements | 10 fc |

| Industrial Lighting Requirements | 10 fc |

| Outdoor Lighting Requirements | 3 fc |

| Parking Lot Lighting Requirements | 3 fc |

1926.800(l)(2) - OSHA standard requiring that portable lighting equipment should only be used within 50 feet of explosives handling within underground environments.

1926.800(m)(9)(i) - OSHA standard requiring that electrical installations in underground areas where oil, grease, or diesel fuel are stored shall be used only for lighting fixtures.

1926.800(m)(9)(ii) - OSHA standard requiring that lighting fixtures in storage areas where oil, grease, or other flammable gasses are stored are approved for Class 1, Division 2.

1926.800(s)(2) - OSHA standard requiring that lighting circuits be placed so that personnel or equipment does not damage circuits or disrupt service.

1926.800(g)(4) - OSHA standard requiring that each employee underground have acceptable PPE with lighting such as a cap light or hand held light in the work area for emergency use.

Class 1 Division 1/Division 2 Lights

Our LED Explosion Proof lights for hazardous areas are Class 1 Division 1 (C1D1) and/or Class 1 Division 2 (C1D2) certified. This means that these fixtures are designed to withstand flammable gasses, vapor, or liquids, as well as lower risk particles such as combustible dusts and ignitable fibers/flyings. In other words, these lighting fixtures can operate in virtually any hazardous environment.