LED High Bay Light Information Center

UFO LED High Bay Lights

One of the most common forms of high bay lighting fixtures is a UFO high bay light. The name UFO is derived from the compact circular design of the fixture. This design allows the fixture to provide accurate and optimal illumination from high areas. The design also ensures durability through harsh environments that are commonly present in industrial settings.

Generally speaking, LED UFO high bays range from 50 watts and 6900 lumens on the lower end, all the way up to high powered 400 watt fixtures with 56,000 lumens. The amount of lumens you need will depend on several factors including ceiling height, dimensions, etc.

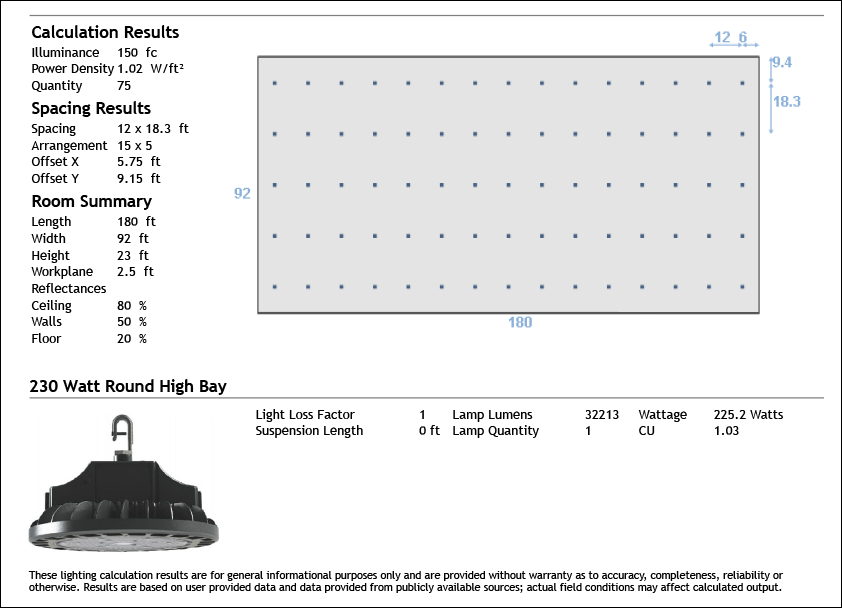

In order to determine the exact number of UFO high bays required to properly illuminate a facility, it’s recommended to use a photometric layout. A photometric plan also allows you to determine the exact number of footcandles and fixture spacing within a designated area.

Here’s an example of a photometric plan created for an industrial facility. In this plan, there were 84 230 watt LED UFO high bay lights at 150 foot candles.

Linear LED High Bay Lights

Another common type of high bay lighting is linear high bay lights. Linear high bays have a strip shaped design. These lights are known for high energy efficiency and are commonly used throughout large gyms, storage facilities, recreational centers, etc. Although these high bays fill many industrial needs, they also have commercial uses such as office buildings and schools.

Generally speaking, LED linear high bays range from 90 watts and 12,200 lumens all the way up to 400 watts and 56,000 lumens. Some of the more modern linear style high bays actually have switches to adjust the power output (watts) and color temperature (kelvin) to desired levels.

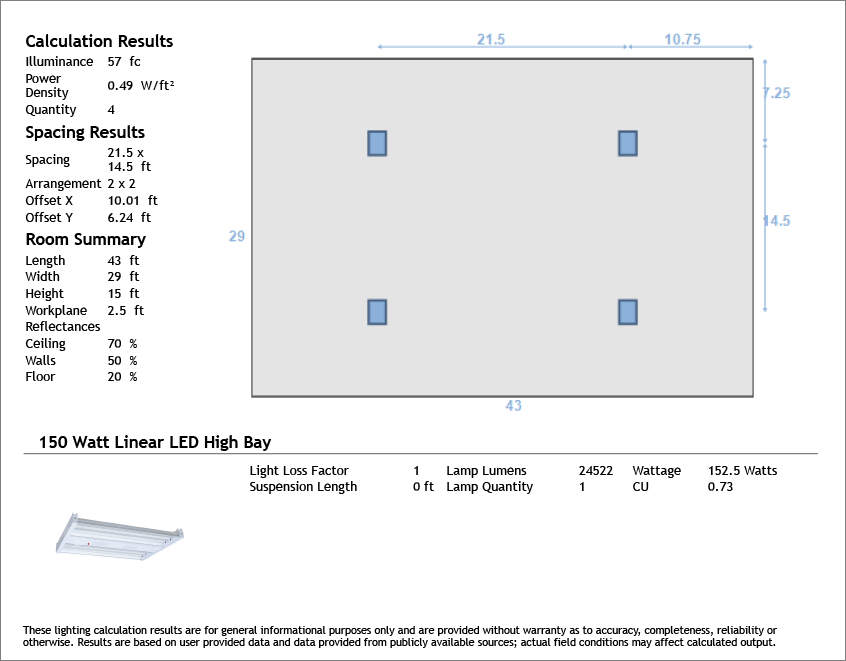

Photometric layouts can be used to determine the exact number of fixtures required to properly illuminate an area. Below is an example of a photometric plan created for a commercial gym. In this plan, there were 4 150 watt LED linear high bays used at 57 foot candles.

Hazardous Location High Bays

Hazardous areas require specific types of high bay lights in order to comply with OSHA and industrial safety regulations. Specifically for areas where there may be hazardous materials, specialized explosion proof high bay fixtures are required. These are divided into two separate categories according to the National Electric Code (NEC), which are known as Div 1 Class 1 and Div 1 Class 2.

Class 1 areas are environments where explosive vapors or gasses are present, presenting the highest risk of explosion. Accordingly, these areas require the highest performing lighting fixtures with the strongest resilience to the ingress of outside contaminants, as well as electronic and electrical shielding. Class 2 areas, while similar, do not require the same level of resilience due to the fact that these areas may have explosive gasses or vapors but it is not a certainty at all times.

Dimmable LED High Bay Lights

Some models of high bay lighting fixtures feature dimming capabilities, with adjustable wattage outputs to suit the specific needs of the application in which they are installed. While traditional lighting such as incandescent fixtures can be dimmed via adjustments in line voltage, the same is not true for fixtures such as LED high bays.

According to the General Services Administration Public Buildings Service, LED fixtures with integrated controls maximize LED savings and simplify installation. In fact, the estimated annual U.S. savings for LED high bay lights is around 46.5 Terawatt hour (TWh). In other words, according to the study, high bays with lighting controls can save around 12% in annual energy costs (GSA, August, 2015, LED Fixtures With Integrated Controls).

These lights instead use a more sophisticated electronics package in order to modulate power output, which is why it is important to look carefully at different high bay fixture options when choosing a lighting system.

Here’s an example of a popular LED high bay light with 0-10 volt dimming LED driver.

Motion Sensor High Bays

In addition to adjustable wattage outputs, many high bay lighting fixtures now feature motion sensor technology, either as an integrated unit or an optional add-on. This new feature has been increasing in popularity over the past decade, due to its effectiveness as well as ease of installation. In the past, multiple motion sensors would be required to be mounted throughout a facility to activate or deactivate lights, which would then independently cycle the power on and off to the lighting system.

With current motion sensor technology being integrated into the fixtures themselves, this eliminates the extra hassles and costs associated with setting up an independent motion sensor system. It also allows for more precise measurement of motion inside a room, which means only the lights in the immediate vicinity of individuals in the room will illuminate versus the entire room at once. This saves electricity and extends useful fixture life, saving a considerable amount of costs over the lifetime of the fixture.

How Many High Bay LED Lights Do I Need?

In order to determine the number of high bay LED lights required to illuminate the space, you’ll need to determine several factors including,

- Ceiling height

- Dimensions of the space

- Facility usage

- Environmental factors

For example if you have a ceiling height that’s under 11 feet, we generally recommend using a high bay fixture that’s between 50-100 watts and 9,000-12,000 lumens.

As ceiling height increases, higher lumen output and wattage will be required to adequately illuminate the space.

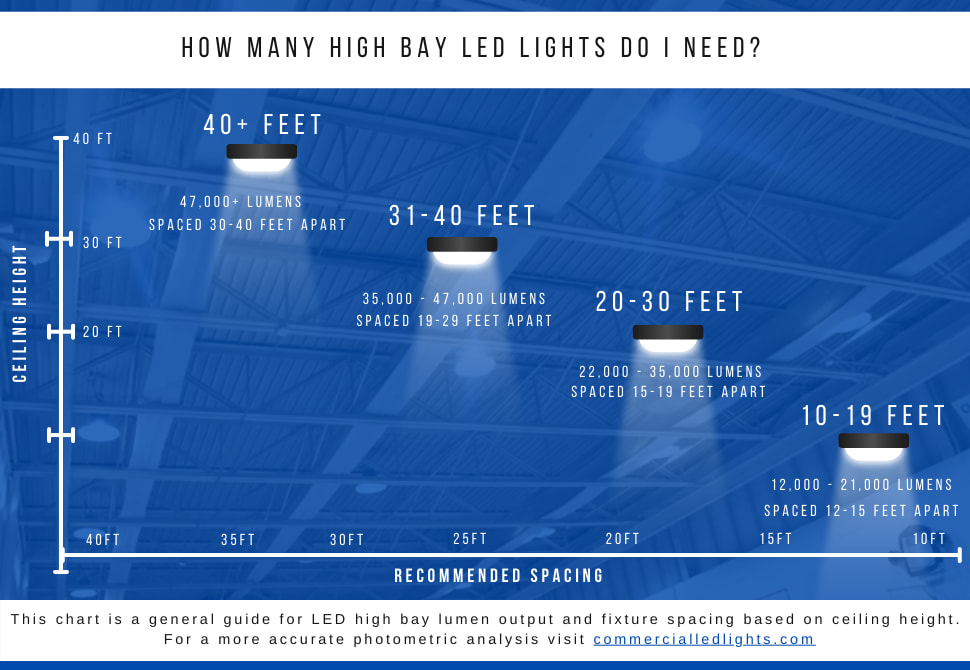

Here are some projections for higher ceiling heights based on our experience.

| Ceiling Height | Recommended Wattage | Recommended Lumen Output |

|---|---|---|

| 10-19 feet | 125-170 Watts | 12,000 - 21,000 Lumens |

| 20-30 feet | 200-300 Watts | 22,000 - 35,000 Lumens |

| 31-40 feet | 300-400 Watts | 35,000 - 47,000 Lumens |

| 40+ feet | 400+ Watts | 47,000+ Lumens |

Additionally, here are some projected spacing for LED high bay lights based on ceiling height

| Ceiling Height | Recommended Spacing |

|---|---|

| 10-foot ceiling | 12-15 feet apart |

| 20-foot ceiling | 15-19 feet apart |

| 30-foot ceiling | 19-29 feet apart |

| 40-foot ceiling | 30-40 feet apart |

Please note, these projections may vary depending on fixture type, environmental factors, etc. Having a photometric analysis conducted on your area is the most accurate way to determine how many high bay led lights you need to illuminate your space.

LED High Bay Applications

LED high bay lights can be used for virtually any application that involves a ceiling height of 15 feet or higher. Realistically speaking, there are far too many possible applications to list; however, we’re going to list some of the more common ones based on our experience.

High Bay LED Lights v.s. High Bay Fluorescent Lights

One of the most appealing benefits of LED lighting is its dramatically increased efficiency compared to traditional types of lighting such as fluorescent, metal halides, sodium lamps, CFL bulbs and HIDs. Warehouses that have switched over to LED lighting have seen as much as an 84% ROI in their lighting operations. This dramatic improvement in ROI is not only due to a 40% increase in efficiency, but also the lifespan of LED bulbs being over three times that of traditional lighting.

Here’s a summary below of a warehouse lighting case study where a metal industry supplier with several warehouses replaced fluorescent T5 lamps with LED UFO high bays. These high bays are one of the many quality solutions offered at our store.

Before and AfterThe warehouse was originally using T5 fluorescent lights in their high bay fixtures. These fixtures were replaced with Apollo LED high bays which potentially doubles the overall rated life hours. As you can see in the images below, switching to LEDs increased the overall brightness within the warehouse space while saving significant costs for their company.

We’ve prepared some information using a case study from a supplier in the metal industry for both heat resistant and corrosion resistant alloys.

Current Annual Lighting Cost

LED Lighting Cost

LED Retrofit Cost

Annual LED Savings

Financial Summary

Frequently Asked Questions

Q. What are high bay lights?

High bay lights are lighting fixtures that are designed to cast illumination from high ceiling heights, generally, around 20 feet on up. They come in both round (UFO) style, as well as linear style depending on the layout of the building.

Q. Where are high bays used?

High bays are used in a wide variety of indoor settings. For example, these lighting fixtures are often used to light the interior of warehouses from high ceiling heights. The types of high bays found in warehouses are often industrial quality. In other words, these warehouse high bays are designed to withstand harsh or demanding environments they may encounter. On the other hand, high bays are also used in less demanding environments such as office buildings or any other ceiling that’s around 20 feet or higher.

Q. How many LED high bay lights do I need?

This will be dependent on several factors, such as the mounting height of the fixtures, as well the layout of the building itself. Additionally, the foot candle requirements vary depending on the particular application, which will affect the type, quantity and placement of high bay fixtures required. A photometric plan is the best way to solve this question.

Q. What are the best high bay LED lights?

There are a number of high performance high bay lights available to choose from. The best light is the one that suits the application requirements as closely as possible. There are certain models that have the ability to utilize motion sensors, in addition to selectable color temperatures and power outputs.

Q. How do you wire high bay LED lights?

These lights are usually hard wired into the building, although in certain instances some customers will wire these in with a removable plug so they can be moved. Generally speaking, we recommend consulting with an experienced electrician and the included installation guides in order to ensure a safe and quality installation.

Q. How do you hang high bay lights?

High bay lights are typically hung via a hook or chain attached to the ceiling above. This allows for simple height adjustments as well as proper ventilation for safety and longevity.

Q. How do you dim LED high bay lights?

Certain high bay lights are either dimmer compatible or have adjustable power output settings on the side of the fixture itself. It is important to select the right model to ensure that it has these capabilities if an end user desires a dimmable option.

Q. What are low bays?

Unlike high bays, low bay lighting fixtures are used to provide lighting in areas with low ceilings. Ceilings that are considered “low” by industry standards are generally under 20 feet. Since these areas don’t require as powerful of a lighting source, low bays are specifically designed to provide necessary illumination without unnecessary consumption of energy.

Q. Where are low bays used?

As the name suggests, low bay lighting fixtures are used to provide illumination from ceiling heights that are considered “low” by industry standards (usually less than 20 ft). These types of fixtures typically don’t have as strong of an energy output due to the lower ceiling to ground height.

Definitions

For the benefit of the reader, we’ve prepared this section which lists common industry terms used by electricians and lighting specialists on high bay lighting.

Lumens – This is the measure of the quantity of visible light emitted. In the past a high bay light's output was typically quantified in wattage instead of lumens due to the linear relationship between wattage and lumen output in traditional incandescent lights. However due to the wide variance in lumen outputs of LED high bay lighting with equivalent wattage, comparing them based on their lumen output is now the industry standard.

Wattage – This is the standard measurement of power consumption for the lighting industry, often used in a ratio to a lights lumen output in order to determine its energy efficiency. A watt is defined as the rate at which work is done when one ampere of current flows through an electrical potential difference of one volt. This can be expressed as [1W = 1V * A].

Voltage – This is defined as the potential for energy to move. Voltage is considered analogous to water pressure, as the characteristics of voltage are similar to that of water flowing through a pipe pressured by a pump.

Color Temperature – Used as a way to define the color hue of a light, color temperature is measured using Kelvins on a scale ranging from 1,000K to 10,000K. The most common color temperatures in commercial lighting today range from 3000K to 6000K, with 5000K being the closest equivalent to daylight.

DLC Listed – Short for “Design Light Consortium”, when a product is listed under this standard it means that it has been certified to perform under high levels of energy efficiency.

Motion Sensor - Used primarily as an energy saving device, motion sensors pickup movement within an area and activate lighting while the facility is being used. This is especially useful in applications using high powered lighting fixtures such as high bays, and can save a considerable amount in annual operating costs.

High Bay Reflector - A decorative cone that fits to the bottom of a UFO style high bay, this serves to improve the aesthetics of the fixture as well as ensure that all light is directed downward. It also helps to reduce side glare.

Yoke Mount Bracket - An alternative mounting option for high bay lights, this bracket is designed to hard mount a high bay fixture to a ceiling. It allows for different angles to tilt the light side to side in order to ensure it is a perfect 90° angle to the floor below.

High Bay V-Hook - Mounted on the backside of a fixture, this hook holds onto a cable to chain in order to suspend the high bay above the area to be illuminated. This is by far the most common type of mounting option for high bays as it is simple and the fixture will self-level, requiring no adjustments aside from height.

High Bay Safety Cable - An additional safety measure, this is a secondary retention system that mounts to the high bay and wraps around a hard suspended mounting point on the ceiling or other area. The idea behind this is to prevent the light falling to the floor in the event the primary mounting system fails during maintenance or regular operation.