Explosion Proof / Hazardous Location Lighting Information Center

Our Explosion Proof Lighting Fixtures

Explosion Proof Lighting Requirements

Environments containing explosive materials, flammable gasses, vapors or dust require the shielding of any possible ignition source in order to maintain a safe workplace. As these environments are almost always indoors, they require artificial illumination in order to ensure proper visibility and safety for personnel. The light fixtures used for this must meet a number of different requirements, including being specifically designed and certified being explosion proof per the UL 844 Standard.

UL 844 Standard certified explosion proof lighting is unique when compared to traditional fixtures in the way in which it is constructed. Unlike most light fixtures which have unshielded electronics, and enclosures that are open to air, explosion proof fixtures are specifically designed to shield and separate electronics and electrical components from the outside environment. They also must be impact and shock resistant in the event of an accident in order to prevent exposing their electronics to the outside atmosphere.

Our specialized explosion proof lighting is designed to meet all NEMA requirements for hazardous environments. They feature sealed impact resistant non-conductive aluminum housings and can be mounted in a variety of different manners to work in different environments. With heavy duty lenses and thoroughly shielded electronics, they are ideal for any hazardous environment that requires serious lumen output.

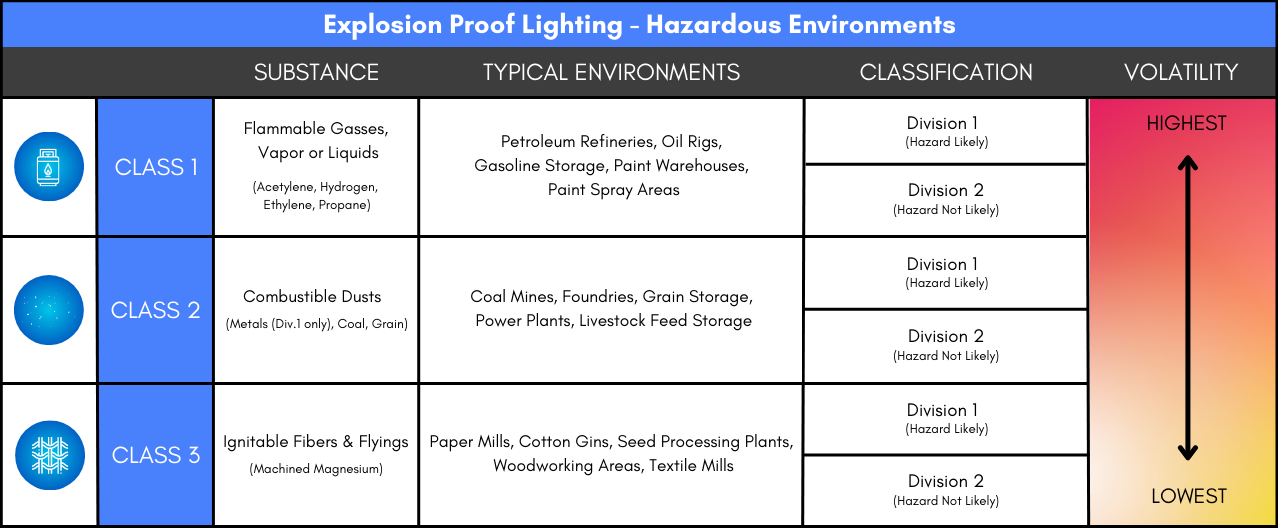

Classes and Divisions for Hazardous Area Lighting

Class I, Division 1 – Class I Division 1 lights are necessary in areas where concentrations of vapors, liquids, or gasses such as gasoline exist within the environment under typical operating conditions.

Class I, Division 2 – Class I Division 2 lights are necessary in areas where concentrations of vapors, liquids, or gasses such as gasoline exist within the environment under atypical operating conditions.

Class II, Division 1 – Class II Division 1 lights are necessary in areas where combustible dust such as coal exists within the environment under typical operating conditions.

Class II, Division 2 – Class II Division 2 lights are necessary in areas where combustible dust such as coal exists within the environment under atypical operating conditions.

Class III, Division 1 – Class III Division 1 lights are necessary in areas where ignitable fibers or combustible flyings such as sawdust exist within the environment under typical operating conditions.

Class III, Division 2 – Class III Division 2 lights are necessary in areas where ignitable fibers or combustible flyings such as sawdust exist within the environment under atypical operating conditions.

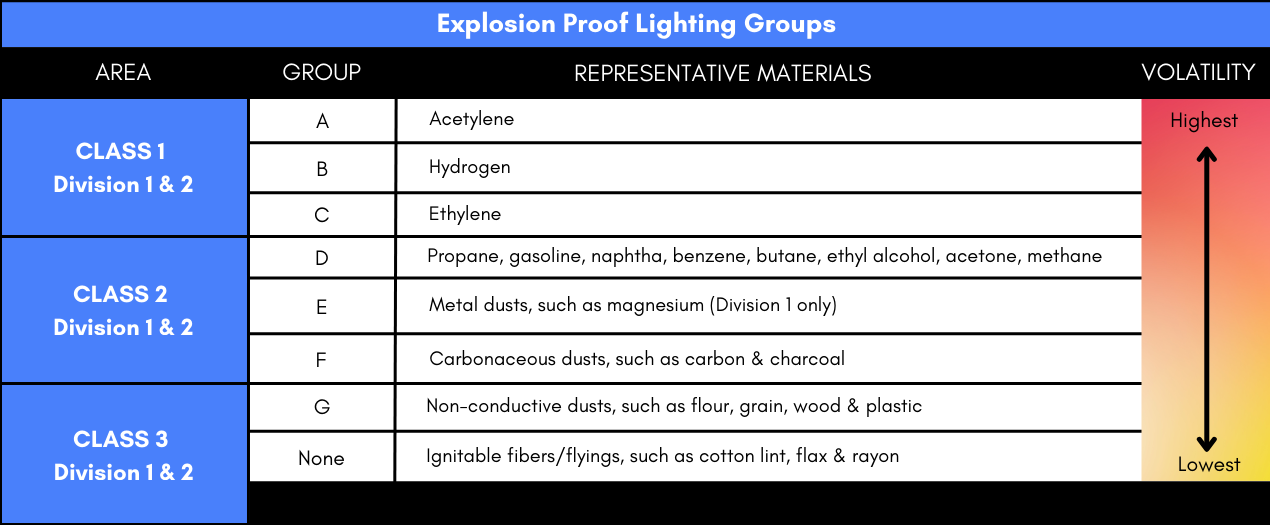

Explosion Proof Lighting Groups

Explosion-proof lighting fixtures are classified into various letter groupings to identify the types of hazardous materials they are designed to safely operate around. These letter groupings, usually ranging from Group A to Group G, are part of a classification system that denotes which types of gases, vapors, and dusts the lighting fixture can be safely used with.

- Group A: Acetylene

- Group B: Hydrogen, butadiene, ethylene oxide, propylene oxide, acrolein

- Group C: Ethylene, carbon monoxide

- Group D: Propane, gasoline, naphtha, benzene, butane, ethyl alcohol, acetone, methane

- Group E: Metal dust including aluminum, magnesium

- Group F: Carbonaceous dust including coal, carbon black, coke

- Group G: Grain, flour, wood, plastic, and chemical dust

Understanding these letter groupings is essential for ensuring the safe operation of lighting fixtures in hazardous environments. Always consult with an expert or refer to the specific guidelines and standards, such as those provided by organizations like the National Electrical Manufacturers Association (NEMA) or Underwriters Laboratories (UL), when selecting explosion-proof lighting.

Explosion Proof Lighting Standards

Standards are typically set by organizations such as the National Electrical Code (NEC) in the United States, or the European Committee for Electrotechnical Standardization (CENELEC) in Europe, and others depending on the region. Other organizations that set explosion proof lighting standards include,

- National Electrical Manufacturers Association (NEMA): NEMA is a U.S.-based organization that sets standards for various types of electrical equipment, including explosion-proof lighting.

- Underwriters Laboratories (UL): UL is a global safety certification company that sets standards and provides testing for a wide range of products, including explosion-proof lighting. In the U.S., UL Standard 844 covers luminaires for use in hazardous locations.

- International Electrotechnical Commission (IEC): The IEC is an international standards organization that prepares and publishes standards for electrical, electronic, and related technologies. Their standards, including the IECEx system, cover explosion-proof equipment.

- ATEX Directive (European Union): The ATEX Directive sets forth requirements for equipment and protective systems intended for use in potentially explosive atmospheres in the European Union.

- National Fire Protection Association (NFPA): The NFPA publishes the National Electrical Code (NEC), which includes guidelines for installing electrical equipment in hazardous locations in the U.S.

- Canadian Standards Association (CSA): In Canada, the CSA sets the standards for explosion-proof lighting.

Each of these organizations has their own set of regulations, codes, and certifications for explosion-proof lighting to ensure safety in hazardous environments. Depending on the specific location and application, different standards may apply.

Explosion Proof Lighting Zone System

The explosion proof lighting zone system is used primarily outside North America in areas such as Europe. Similar to the class and division system, the zone classification system is used in hazardous environments to indicate the type of lighting fixtures that can be used safely. This system is based on the potential for explosive gasses or dust to be present in a particular area.

In this system, hazardous environments are divided into zones based on the likelihood and frequency of the presence of explosive gasses or dust.

The three main zones are:

Zone 0: An area where explosive gas or dust is continuously present or present for long periods of time.

Zone 1: An area where explosive gas or dust is likely to be present under normal operating conditions.

Zone 2: An area where explosive gas or dust is not likely to be present under normal operating conditions, but may be present for short periods of time.

Explosion-proof lighting fixtures are designed and rated for use in each of these zones. These fixtures are constructed in such a way that they will not ignite any flammable substances that may be present in the environment. They are also designed to withstand the potential for explosions, preventing sparks or arcs from being generated.

Talk to a Hazardous Location Lighting Expert

Due to the nature of hazardous industrial environments, there is little margin for error when it comes to electrical safety and preventing accidental ignition of fumes, vapors or combustible dust. Choosing explosion proof lighting is the first step in ensuring hazardous environment safety, but these lights need to be selected and configured properly in order to operate to their maximum potential.

Working with a lighting expert specializing in explosion proof lighting is key to ensuring the best possible setup that also meets industry safety standards. This expert can also work with end users to create a photometric plan that provides the proper foot candle levels as well as optimal energy efficiency.

Explosion Proof Lighting Accessories

LED explosion-proof lighting accessories are additional components or features that can be added to explosion-proof LED lighting fixtures to enhance their functionality, safety, or durability. These accessories may include but are not limited to the following:

Cable Junction Box

Straight Swing Pipe

90 Degree Stanchion Arm

Stanchion Arm

Bended Pipe

Straight Chain

Hook Mount

What is The Cost of Explosion Proof Lights?

The cost of explosion-proof lighting fixtures can vary depending on several factors, including the type of fixture, the level of explosion protection required, the materials used in construction, and the manufacturer.

As a general estimate, basic explosion-proof lighting fixtures can start at around $100, while more advanced and durable fixtures can cost several hundred or even thousands of dollars.

Generally speaking, if you find an explosion proof lighting fixture that’s under $400, it’s unlikely that this fixture is properly certified to withstand hazardous environments.

The explosion proof lighting fixtures at our store range from $435 up to $1,436 depending on the style, power, and environment where the fixture needs to operate in.

Explosion Proof Lighting Applications

Explosion proof lights are used in hazardous areas that have a high risk of accidental fires or explosions. These environments usually have some level of flammable gasses, vapors, dust or liquids that are present that can potentially ignite and create explosions. Common applications include but are not limited to the following:

- Chemical Processing

- Chemical Storage

- Grain Processing / Storage

- Power Plant Lighting

- Oil & Gas Lighting

- Oil Rig Lighting

- Petrochemical Lighting

- Mine Lighting

- Marine Environments

- Engine Room Lighting

- Paper Mill Lighting

- Distilleries/Alcohol Production

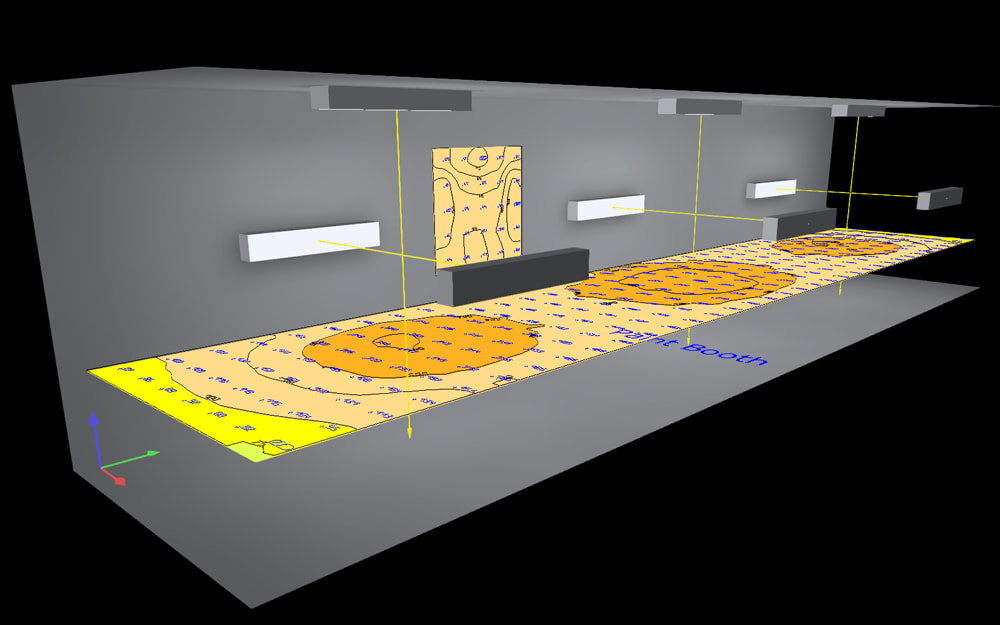

Paint Booth Lighting Design

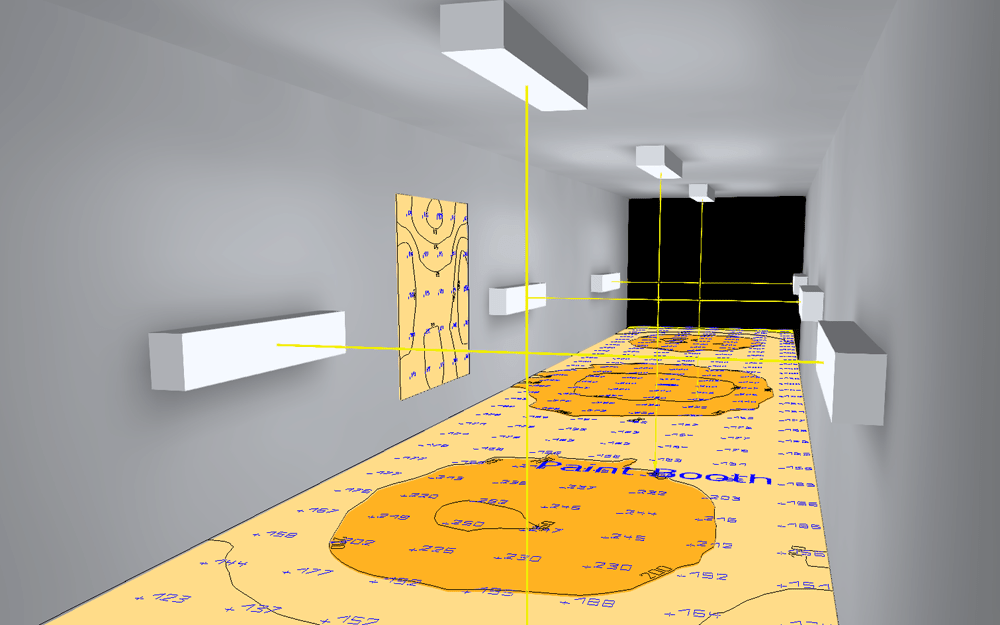

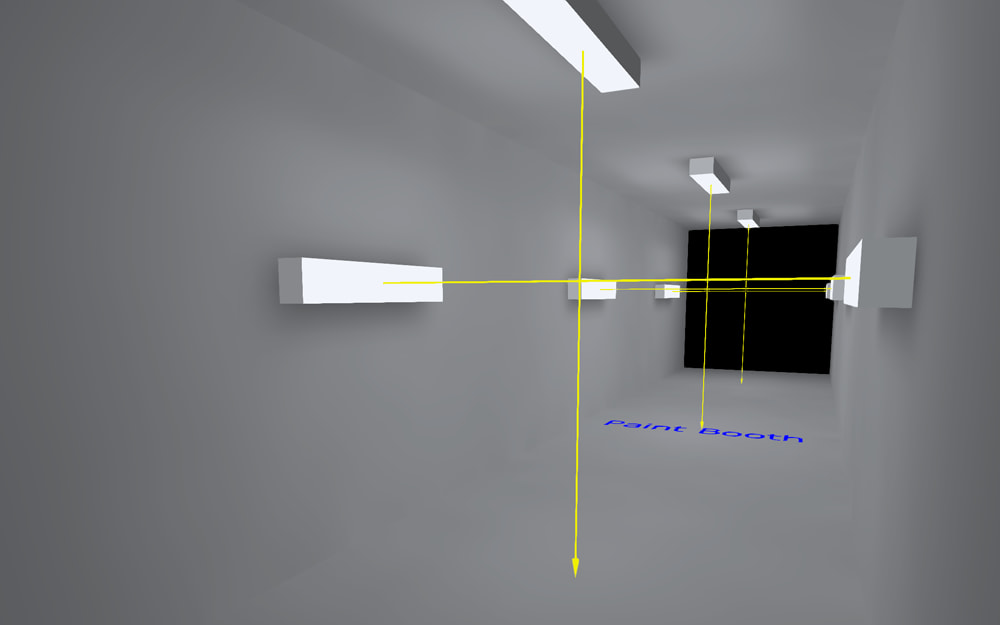

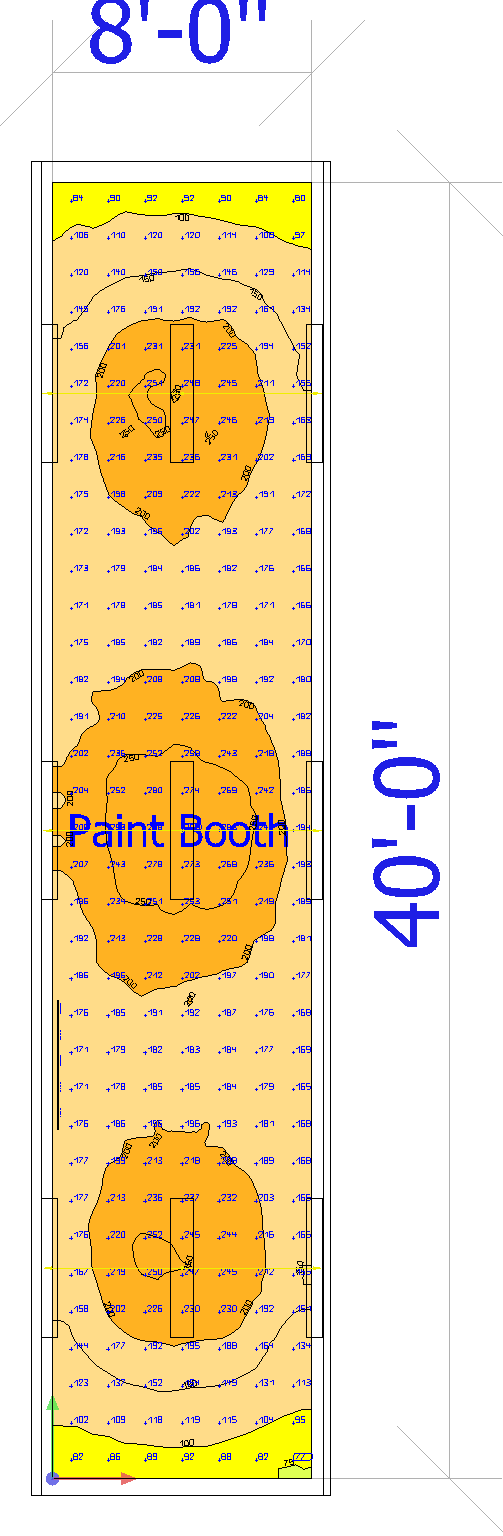

Here’s an example of the 3D paint booth lighting photometric design conducted by our professional lighting engineers. In this example nine 60W LED Explosion Proof 1×4 Vapor Proof Lights were used on a 40×8 foot paint booth with 9 foot ceilings. The fixtures were mounted on the wall and provided a maximum of 290 foot candles with a uniformity of 1.22-3.96.

Explosion Proof Lighting Layout

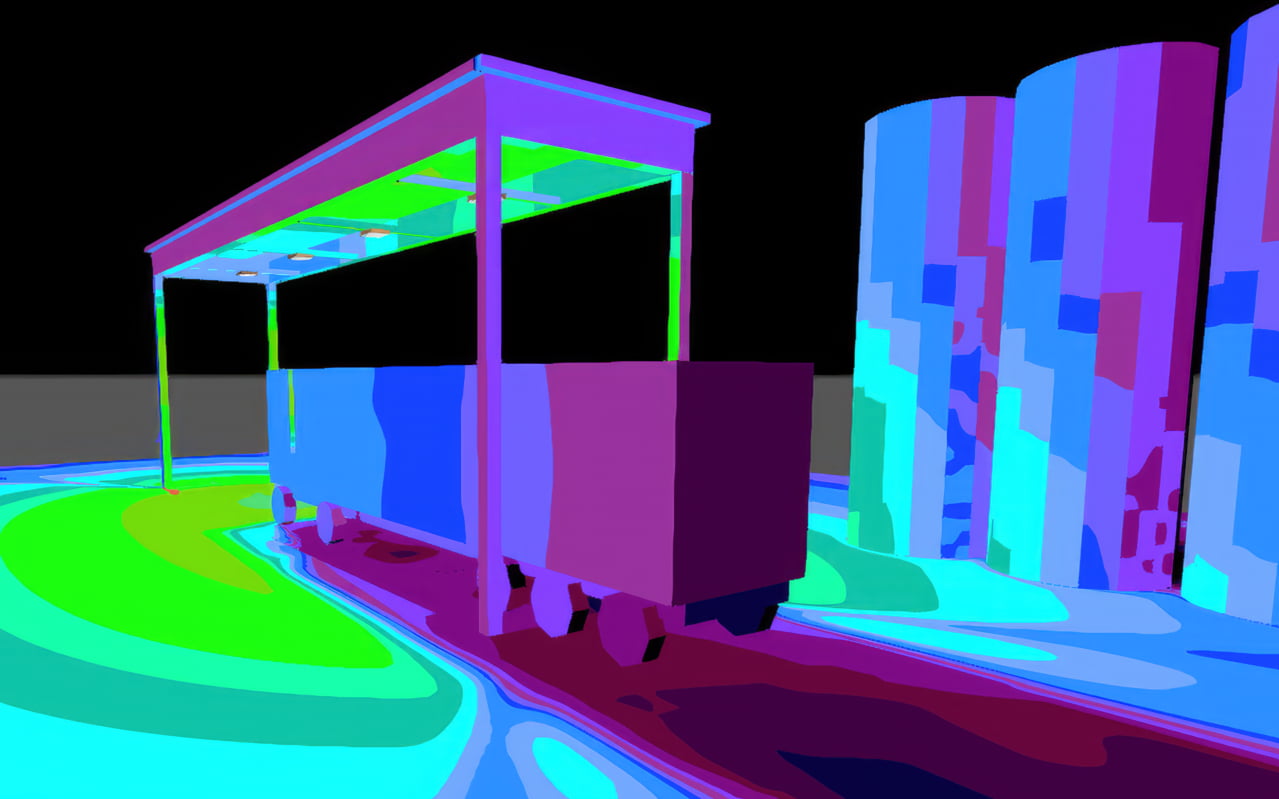

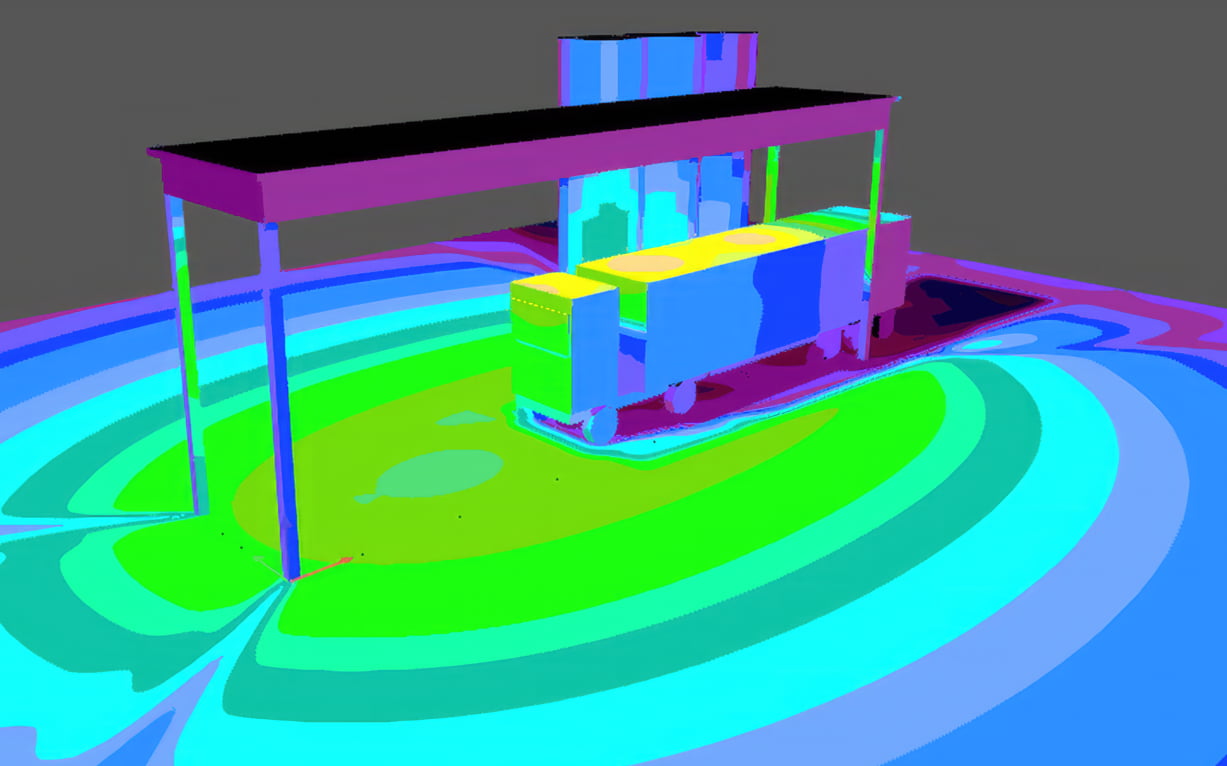

Our LED lighting experts designed a explosion proof lighting layout for a tanker fuel pumping station. Using photometric software we placed 4 LED round explosion proof lights around the area to ensure 30 foot candles of illumination

Frequently Asked Questions

This section provides answers to commonly asked questions in relation to explosion proof lighting. Visit our hazardous lighting FAQ page for a full list of expert answers to commonly asked questions.

Q. What is explosion proof lighting?

This is lighting that is intended for hazardous environments containing combustible dust or flammable gasses, such as a manufacturing facility, petroleum refinery, chemical plant, etc. These fixtures feature heavy duty sealed housings and shielded electronic components.

Q. What are hazardous area lights?

Hazardous area lights, sometimes also referred to as hazardous location lights or hazloc lighting, are designed to be used in environments where there is a risk of explosions or fires due to the presence of flammable gasses, vapors, dust, or fibers. These environments include oil and gas refineries, chemical plants, mining sites, grain storage facilities, and many other industrial settings.

Q. What’s the difference between explosion proof lights and hazardous area lights?

Explosion-proof lights fall under the broader category of hazardous area lights. Specifically, explosion-proof lighting is designed to contain any sparks or explosions that occur within the fixture itself, preventing them from igniting flammable materials in the surrounding environment. This is achieved through the use of robust, often cast metal enclosures and design features that cool escaping gasses below their ignition temperature.

So, while all explosion-proof lights are hazardous area lights, not all hazardous area lights are necessarily explosion-proof. There are other types of hazardous area lighting, such as intrinsically safe lights, which are designed to limit electrical and thermal energy output to a level below what might ignite specific hazardous atmospheres.

Q. How does explosion proof lighting work?

The purpose behind lighting being explosion proof is to prevent combustible dust or gasses coming in contact with electronic or electrical components. In order for this to be achieved, fixtures must feature heavy duty housings that are thoroughly sealed from the outside atmosphere, and usually have special extra steps taken to properly shield electronics.

Q. Where is explosion proof lighting required?

This type of lighting is specifically required in any hazardous environment that contains potentially combustible gasses or dust. These are usually industrial manufacturing or production facilities, such as chemical plants, metal foundries, etc.

Q. What is Class 1 Div 1?

This is an area where gasses, vapors or liquids may exist under normal conditions that have the potential to become flammable or ignitable.

Q. What is Class 1 Div 2?

This is an area where explosive or flammable gasses, vapors or liquids usually will not be present under normal conditions.

Q. What is the difference between Class 1 Div 1 and Class 1 Div 2?

The primary difference between these two classes has to do with the likelihood of the presence of flammable, explosive or otherwise ignitable gasses, vapors or liquids in a particular area. Class 1 Div 1 is a higher risk environment where the possibility of accidental or unintentional explosions can happen, whereas Class 1 Div 2 is a lower risk environment where the possibility of this occurring is substantially reduced.

Why Use LED Explosion Proof Lighting?

Explosion-proof LED lighting provides several advantages, particularly in hazardous environments where there’s a risk of flammable gasses, vapors, or dust. Here are a few reasons why you should consider using explosion-proof LED lighting:

Safety: These fixtures are specifically designed to contain and isolate potential ignition sources, thereby preventing the ignition of the flammable atmosphere in the surrounding environment. This significantly reduces the risk of explosions.

Energy Efficiency: LEDs consume less power than traditional lighting solutions like incandescent or fluorescent lights, which can lead to significant energy savings over time.

Longevity: LEDs have a long lifespan, typically between 25,000 to 100,000 hours of operation. This means they need to be replaced less often, reducing maintenance costs and downtime.

Durability: Explosion-proof LED lights are typically made with rugged materials to withstand harsh conditions. They’re resistant to shock and vibration, which is beneficial in industrial settings.

Brightness and Light Quality: LEDs provide bright, high-quality light, which is crucial for ensuring safe working conditions in hazardous areas. They also have the ability to reach full brightness instantly.

Eco-Friendly: LEDs are more eco-friendly than many traditional light sources, as they contain no toxic elements such as mercury, emit less CO2, and because of their longer lifespan, result in less waste.

Cost-Efficiency: Although the upfront cost of explosion-proof LED lights might be higher, their long lifespan and energy efficiency can lead to lower overall costs in the long term.

Given these advantages, explosion-proof LED lighting is an excellent choice for industries such as oil and gas, chemical manufacturing, mining, and others where hazardous conditions may exist.