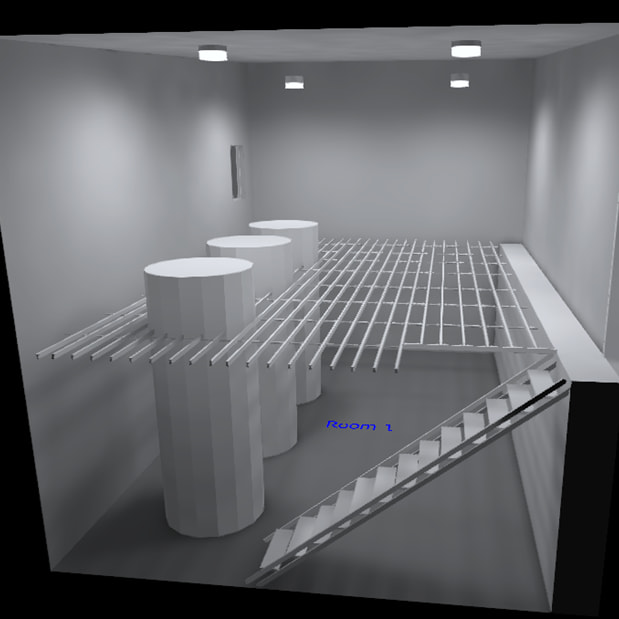

In this case study, we explore the installation of specialized lighting within the chemical mixer expansion project. The project involved the strategic placement of four 150W Class 1 Division 1 (C1D1) round explosion-proof lights, mounted at a height of 13 feet.

The room size is 24×33 feet, with two distinct levels:

- Sub Level Grading Height (10 feet)

- Main Level Ceiling (14 feet)

After a thorough evaluation, our team concluded that these explosion-proof lighting fixtures were ideally suited to meet the stringent safety requirements of the chemical mixer area while providing effective illumination. The lighting setup ensures both safety and visibility, exceeding the IES recommended illumination levels for hazardous environments. This installation highlights our commitment to providing robust and reliable lighting solutions for complex and safety-critical projects.

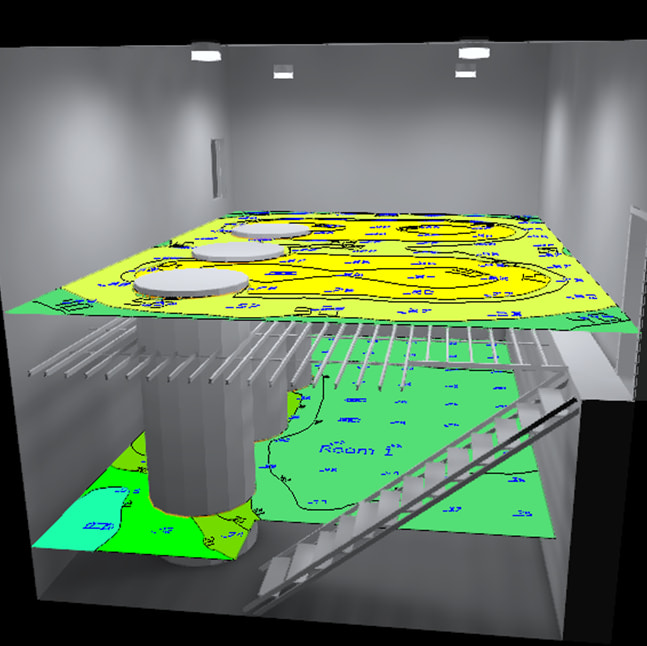

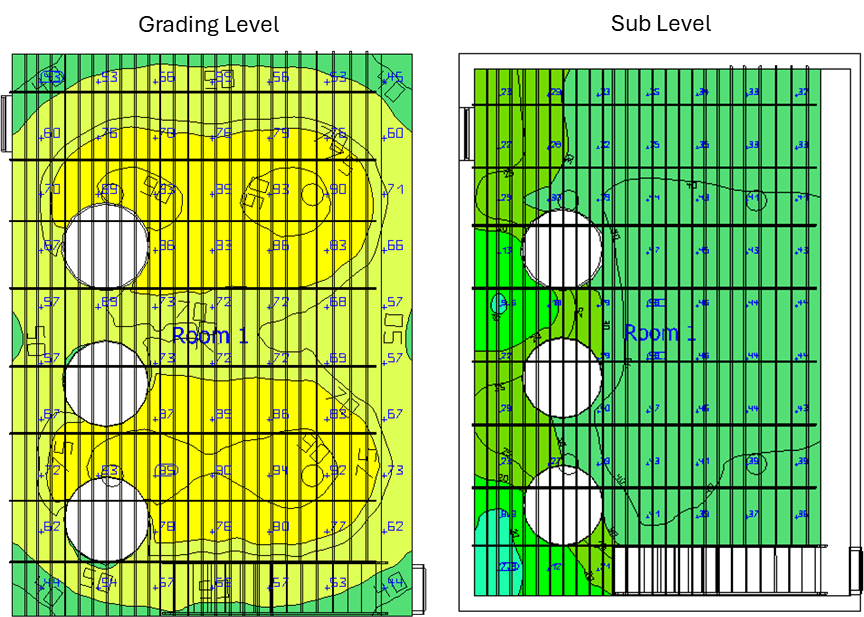

Chemical Plant Lighting Design

Here’s an example of the chemical plant lighting photometric design constructed by our professional lighting engineers. In this example, Four 150W C1D1 Round Explosion Proof Lights were mounted at 13 feet in a room that’s 24x33ft. The sub level grading height was 10 feet and achieved an illumination average of 70fc while the main level ceiling was 14 feet with an illumination average of 34.5 fc.

Fixture Type 1: 150W C1D1 Round Explosion Proof Lights

Fixture 1 Count: 4

Chemical Plant Room Dimensions:: 24ft x 33ft

Ceiling Height: 13ft

Average Illumination: 34.5 fc

Results

The installation of the 150W C1D1 round explosion-proof lights in the chemical mixer expansion project achieved outstanding results. The lighting provided an average illumination of 70 foot-candles at the sub-level grading height (10 feet) and 34.5 foot-candles at the main level ceiling (14 feet). These levels surpassed the recommended illumination standards for such environments, ensuring superior visibility and safety.

This enhancement not only improved visibility and safety within the chemical mixer area but also significantly reduced energy consumption and maintenance demands. The robust and efficient lighting solution aligns with broader sustainability objectives, highlighting our commitment to providing top-tier, eco-friendly lighting solutions for hazardous industrial environments.