The Occupational Safety and Health Administration (OSHA) estimates that at any given time in the United States, there are over 250,000 crane operators and 175,000 cranes in operation on construction sites and on loading docks.

Cranes are intrinsically important pieces of industrial equipment but they are also one of the most dangerous pieces of equipment on a construction site. If safety regulations and protocols are not followed, crane accidents will happen and most injuries stemming from crane accidents are very severe and frequently fatal.

Some of the most common injuries incurred in a crane accident are:

- Broken bones and organ damage

- Traumatic brain injuries and head injuries

- Crush injuries

- Spinal cord injuries

- Full or partial paralysis

- Amputations

- Back injuries

- Electrocution

- Death

Crane Accident Causes

Accidents involving overhead cranes can be caused by a multitude of reasons. A wide range of individuals are at risk for these accidents, including bystanders, dock workers, construction personnel and even crane operators themselves. In fact, approximately 10% of these crane accident injuries are suffered by the crane operators themselves.

The most common type of crane accident is when an individual is struck by an object that has become dislodged and fallen off the crane or its load. In these situations, the individual is underneath a crane while it is in operation, which is something that should never occur. These accidents can be catastrophic, resulting in workers being crushed by heavy loads, or permanently disabled due to serious injury.

In addition to this, there are other issues that occur from lack of situational awareness. Oftentimes, workers or other personnel are not aware of a crane’s current position, and are inadvertently in its path of travel. This can result in workers being struck and even possibly crushed by the crane load, hook or even the crane carriage itself. All of these issues are preventable with proper safety procedures and precautions.

One of the most serious causes of crane accidents are when cranes are used improperly. There are many ways in which a crane can be misused. Improper loading can cause cranes to tip over, exposing workers not only to falling loads but also the crane itself and all of its related hardware collapsing upon them. Also, when operators fail to ensure their path of travel is clear, they can cause the crane to collide with other pieces of equipment, workers and even electrical lines. This can cause objects and other equipment to fall on workers, causing serious injury or even death.

Possible Legal Consequences

Injuries caused by crane accidents can be catastrophic and result in millions of dollars for emergency trauma care and other medically-related treatment.

Due to the chaotic nature of work and construction sites, it may be challenging to accurately pinpoint who is responsible for the accident. As a result, personal injury and workers compensation lawyers are often hired on behalf of victims to investigate the cause.

Depending on the nature of the accident, victims who are seriously injured may be entitled compensation for the costs associated with hospitalization, surgical procedures, medications, home health care, rehabilitation and other treatment modalities. If the injuries are permanent, they may never be able to return to work. The pain and suffering endured by victims and their families can be devastating and result in substantial injury settlements.

OSHA Crane Safety Regulations

OSHA 1910.179 (Overhead and Gantry Crane Regulations)

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.179

This OSHA regulation covers the definitions, terms and general safety guidelines surrounding the operation, inspection and maintenance of overhead and gantry cranes designed to carry heavy loads. Specifically this includes equipment and machines that lift and lower loads using an integral hoist or hoisting mechanism, while simultaneously being able to move them horizontally on an x-y axis. The regulation includes both fixed and mobile cranes, which can be either manually driven or power operated. These canes are usually either cab-operated, floor operated, overhead traveling cranes, remote-operated or power-operated.

OSHA Overhead Crane Training Requirements

https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.1427

This regulation details the current and revised training requirements for crane operators. While employers and crane operators can still perform training and certification for cranes based on capacity, OSHA only now requires that operators be certified by crane type regardless of load. While this makes it easier and simpler for crane operators, this regulation does come with a caveat for employers.

Under these rules, employers are no longer able to rely solely on outside certification for their crane operators. They must regularly conduct in-house training and evaluations to ensure their crane operators are capable of operating their machinery to federal safety standards. Documentation of this training and proof of operator evaluation must remain on site in the event that on site OSHA inspectors request it.

Crane Accident Prevention

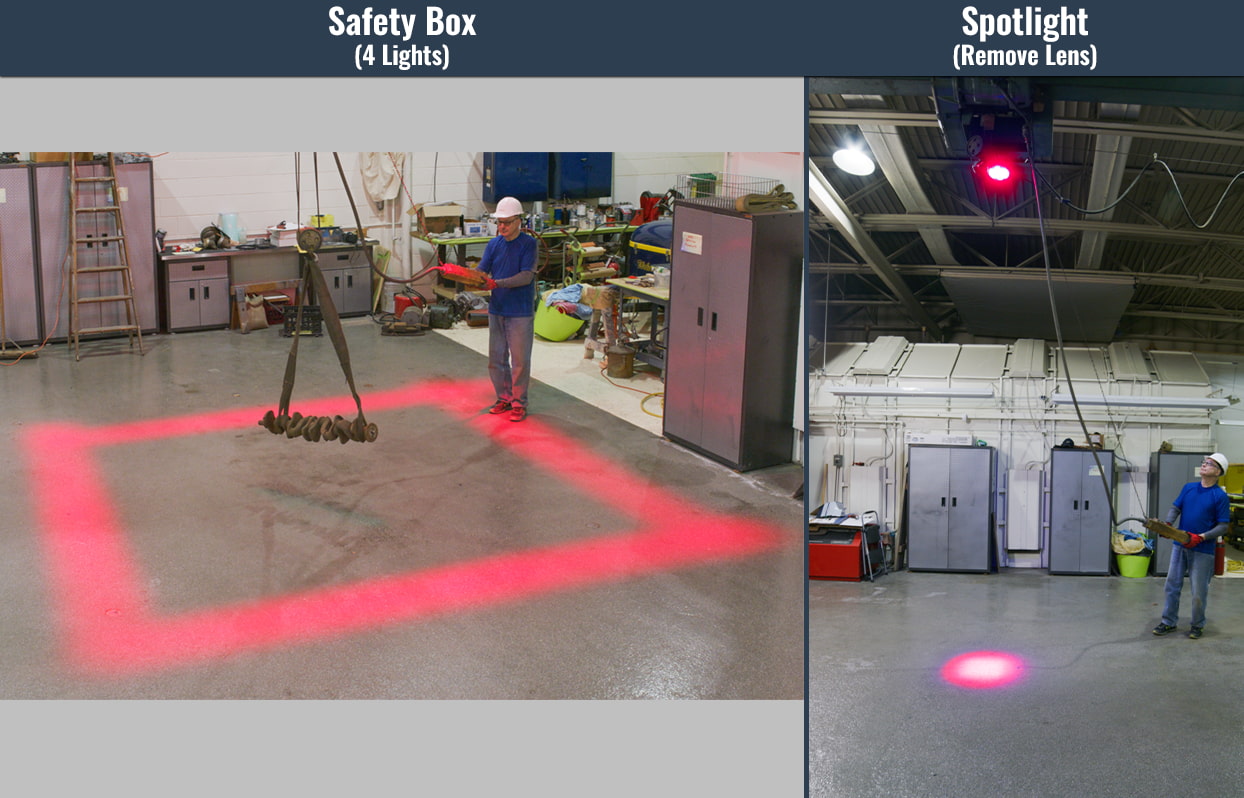

Crane Safety Lights – One of the more modern solutions for crane safety is using LED lighting to illuminate the area surrounding the crane head and/or the load it is moving. This additional layer of safety is relatively inexpensive and easy to set up, yet it results in exponentially higher workplace safety for crane operators, personnel and everyone in the vicinity of heavy cranes.

Crane Safety Training – Training is vital to ensure the safety of both crane operators themselves and the surrounding personnel. The Occupational Safety and Health Administration (OSHA) offers detailed training guidelines for employers and crane operators to ensure the safest workplace possible.

Crane Operator Hand Signals – Even in today’s modern workplace with easy communication via radios and other forms of electronic communication, visual hand signals are still a fundamental form of communication for crane operators and workers. With visual line of sight communication, there is minimal possibility for misinterpretation of intentions, instructions and warnings.

Following OSHA Safety Guidelines – The Occupational Safety and Health Administration has a number of guidelines and regulations surrounding the operation and use of heavy overhead cranes. These guidelines exist in order to protect workers, operators and other personnel in the vicinity of overhead and gantry cranes. Following these guidelines ensures the best possible workplace environment and continued successful operations.