Lighting technology has advanced rapidly in the past decade thanks to new innovations in LED technology. LEDs, short for Light-Emitting Diodes, have seen widespread use since their commercial introduction nearly six decades ago as simple indicator lights for items such as control panels, stereos and various other types of electronic equipment. Today, LEDs have progressed to the point where they are fulfilling some of the most demanding lighting applications on the planet.

While the basic concept behind the technology is similar to that of most other lighting types, there are significant differences in how LED technology operates compared to all other lighting types. Understanding these differences is important when shopping for LED lighting options, especially for those who are replacing existing traditional fixtures such as those using fluorescent, HIDs and incandescent technologies.

History

The beginnings of LED technology dates all the way back to the discovery of electroluminescence in 1907 by English experimenter H.J. Round of Marconi Labs using a crystal of silicon carbide and a cat’s-whisker detector. This created the foundation for the creation of the first LED in 1927 by Russian inventor Oleg Losev, who shared his research in Soviet, German and British scientific journals.

In the following decades, there were multiple experiments and advancements that touched on the concept of an LED in the decades following Losev’s work. However, it wasn’t until the discovery of near-infrared light emission by James R. Board and Gary Pittman of Texas Instruments in 1961 that the reality of practical LED usage was made possible. On August 8th of 1962, the two engineers filed a patent for “Semiconductor Radiant Diode” based on their work, which the U.S. Patent Office granted for their GaAs infrared light-emitting diode, under U.S. Patent No. 3,293,513.

The work from Texas Instruments was expanded upon by Hewlett-Packard (HP) to create cost effective LEDs for the commercial market. Beginning in 1962, HP engaged in research and development to find a way to improve the performance of LEDs, while simultaneously reducing their costs in order for them to be used in common consumer goods and electronics. In addition to HP’s own R&D team, there were also collaborative efforts with the Monsanto Company, who at the time were the sole manufacturer of raw Gallium Arsenide Phosphide semiconductor material, a critical component of LEDs.

This collaborative R&D effort paid off in 1968, with the simultaneous introduction of HP’s LED display and Mosanto’s LED indicator lamp. These were the first commercially viable LED products and sparked a revolution in digital display lighting, replacing nixie tubes as the primary display technology as well as neon and incandescent for indicator lights. Over the next several decades, LED technology continued to improve, offering additional colors as well as increased durability, longevity and overall performance.

With the advent of High-power LEDs (HP-LEDs) over the past decade LEDs have come to completely dominate almost every concerable lighting application in existence. Beginning in specialty applications such as flashlights and compact spotlights for commercial, military and industrial applications, HP-LEDs have made their way into common consumer lighting applications, such as LED tubes, bulbs and even dedicated LED lighting fixtures.

With HP-LEDs, the quality of the light produced has progressively improved along with lumen output. This quality of light, measured using the Color Rendering Index (CRI), has now surpassed practically every other form of light outside of natural daylight. Following Haitz’s law, the overall progression of LED technology will continue to increase exponentially with inversely proportional costs making the technology more economical for widespread use. Like their past, the future of LEDs continues to be bright.

How LEDs Work

As mentioned previously, Light-Emitting Diodes work along the same basic concept as traditional lighting sources – they generate light by electrical current flowing through them. This is where the similarities end however. Unlike traditional lighting sources which rely on heat or a chemical reaction in order to produce illumination, LEDs rely on a semiconductor for their light source. This is a unique technology that offers significant technological benefits and far greater potential for continuous advancement.

To explain how LEDs work, it is important to first understand what a semiconductor is and how it functions. Semiconductors are materials with varying ability to conduct electrical current. Light-emitting diodes are some of the simplest types of semiconductor in existence. Most semiconductors have impurities added to them in order to allow electrons to flow through, since on their own pure semiconductor material is a poor conductor. When a semiconductor has impurities added, this is referred to as doping.

Generally speaking, these semiconductors are made of aluminum-gallium-arsenide (AlGaAs). When this material is doped, it can either add free electrons or create holes in the material where electrons can go. When a semiconductor has extra electrons, it is known as an N-type material since it has extra negatively charged particles. When there are extra holes in the semiconductor, it is known as a P-type material since it effectively has extra positively charged particles.

The basic construction of a diode consists of a section of N-type and P-type material bonded together with electrodes on each end. In this arrangement, electricity is only conducted in a single direction. With no voltage applied, a depletion zone is created between the P and N type materials, restoring the semiconductor to its original insulating state where no electrons or electricity can flow.

In order for the depletion zone to be removed, electrons must be moved from the N-type area to the P-type area, as well as the holes in the reverse direction. Once this occurs through a significant enough voltage, the depletion zone is removed and the charge moves across the diode. It is this interaction between the electrons and holes that generates the light seen in an LED.

Specifically, the light generated by an LED is actually a result of the release of photons from the movement of these electrons from one orbital of an atom to another. The greater the distance between orbitals, the greater the energy released by an electron during the interaction and the higher the frequency of light produced. Inversely, the shorter the distance between orbitals, the lower the energy released during the interaction and the lower the frequency. Lower frequencies are often in the infrared portion of the light spectrum which means it is invisible to the human eye.

This variability in an electron’s orbital change is responsible for the wide range of color temperature options available in LED lighting today. Compared to traditional lighting with fixed or restricted color temperatures, LEDs offer a nearly endless range of possibilities for every type of bulb. In fact, certain LED fixtures offer the option for the user to easily switch between different color temperatures.

Overall Construction

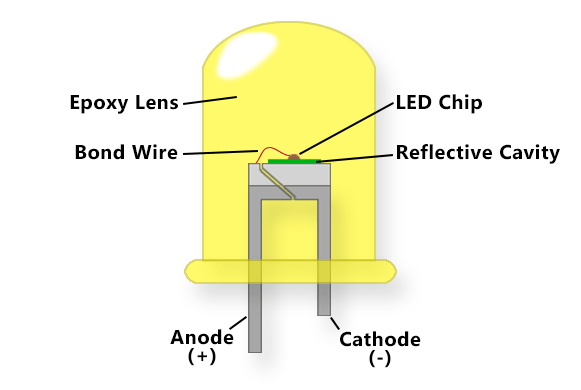

Outside of the semiconductor diode, there are several other key components of an LED that are required in order for it to function. These include the leadframe made up of the post and anvil, the reflective cavity, wire bond and the epoxy lens or case. Certain LED designs may include additional parts or have further sophistication, but all contain these basic parts. Below is a detailed list of each of these components.

Leadframe – Outside of the semiconductor die, the leadframe is the heart of an LED chip. This consists of an anvil, which is negatively charged and holds the semiconductor material itself, and the post, which is positively charged and contains the wire bond which provides current into the die. These two components of the leadframe do not physically touch, and are only connected via the wire bond.

Reflective Cavity – This is a reflective material that surrounds the semiconductor die, directing all light outwards towards the lens. It is usually many times larger than the die itself.

Wire Bond – This is the tiny filament of wire that runs from the post to the center of the semiconductor die, providing it current.

Epoxy Lens/Case – This provides protection and structural stability to the LED unit, rigidly affixing all components in place. It offers a degree of impact protection, as well as significant vibration resistance, which is critical for industrial or high performance applications.

Sub-Types

All Light-Emitting Diodes are built on the same basic principle and components. However, there are some significant differences in the design between these different technologies, which are detailed in the following diagrams.

Standard Diode – This is the most basic form of LED, and also the oldest. It involves a relatively straightforward circuit consisting of an anvil and a post, with a wire bond electrically connecting the post to the semiconductor material in the anvil. All of these components are encased in an epoxy resin lens/housing, with anode and cathode connections ready for easy soldering to a board.

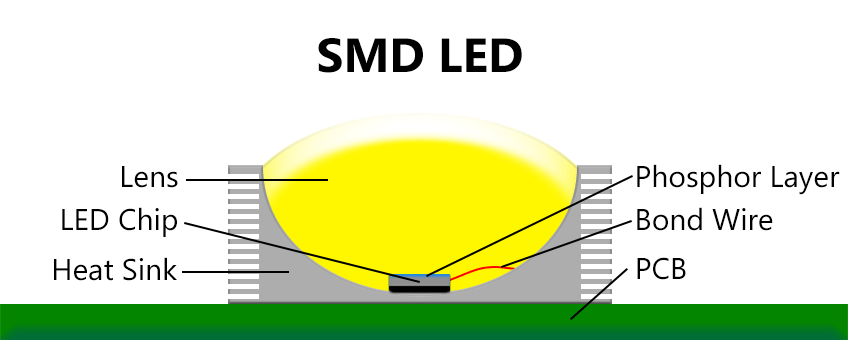

SMD LED – Short for “Surface Mount Device”, these LEDs are unique in that instead of being individual parts that are manually soldered to a board, they are actually mounted onto the board itself. One of the biggest advantages of this design is that the LED mount acts as a heat sink, allowing higher current flow and higher efficiency, generating more light.

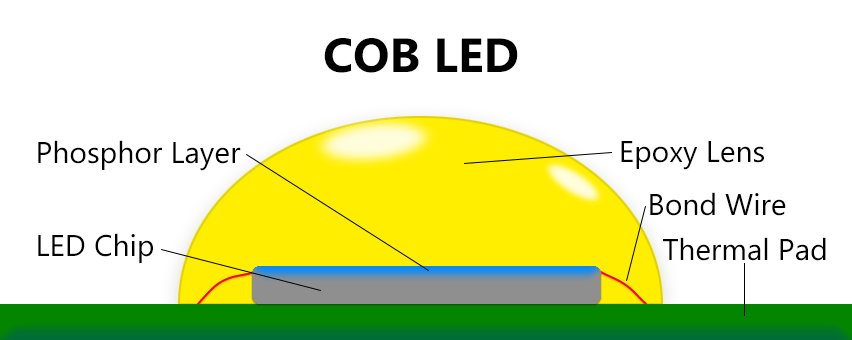

COB LED – Standing for “Chip on Board”, this is an evolution of the SMD design. In this design, the LED chip is mounted directly to the circuit board using thermal adhesive. This allows for further efficiency in cooling, due to the direct contact between the semiconductor die and the board. The increase in cooling efficiency over SMD designs allows even greater efficiency and performance.

Supporting Components

While the semiconductor diode is the central piece of a LED light, there are other components required to make it function properly. LEDs operate on a relatively low voltage, normally in the range of 3 to 3.6 volts. While this works great in low voltage circuits and equipment such as mobile phones and other battery powered devices, the higher voltage provided by household power is not suitable for LEDs on their own.

Not only is household power in the 120 to 240 volt range, it is also alternating current (AC) which is incompatible with LEDs that require direct current (DC). This requires the use of conversion circuitry which can transform household line AC voltage to DC voltage in a usable range for LEDs. There are several components of this circuitry which are listed below:

Input Fuse – This is a vital component to prevent catastrophic disintegration in the case of a short circuit or overcurrent failure. Input fuses are required by fire safety codes, with the option of using printed circuit board conductors or traditional fuses for this purpose.

Input Transient Protection – This is to protect against outside electromagnetic fields, such as that experienced during an electrical storm or lightning. Movistors are typically used for this purpose, and are particularly important for high performance LEDs that have tighter voltage margins.

Bridge Rectifier – Because LEDs operate on direct current and not alternating current, a rectifier is required. Bridge rectifiers are used for this purpose, as they provide full wave rectification by utilizing both halves of the incoming waveform for the greatest efficiency possible. Additionally, unlike other types of rectifiers, these do not require a centre tapped transformer which would be ill suited to LED applications.

Capacitor Smoothing – Because the waveform that comes from a bridge rectifier consists of a constant series of half waveforms that rise and fall between peak voltage and zero voltage, a capacitor is required to smooth out the voltage coming into the circuit.

DC-DC Converter – The drivers for LEDs are pretty straightforward and consist of a low cost DC-DC converter. This provides a constant source of current for the LEDs, allowing them to function.

Heat Sink – Modern LED applications are considerably more demanding than those of simple indicator lights of the past, requiring what are known as High-Power LEDs (HP-LED). These generate a considerable amount of heat, requiring a heat sink to properly dissipate heat in order to prevent damage.

Applications Beyond Lighting

An interesting application not often considered for LEDs is in the communications realm. One of the unique characteristics of light-emitting diodes is that they cycle on and off millions of times per second, very high data bandwidth can be achieved. This means that they can be used for communication purposes, effectively becoming wireless routers to transmit information to and from various devices.

As long as the communicating devices are in a well lit area with a clear field of view, this can be a highly effective method of communication, taking the place of a high speed wifi internet connection while using a fraction of the energy. In fact, this is the exact principle of how fiber optic cables work – communication via light transmission. The one downside to this is that unlike RF transmission such as wifi, the signal will not be able to penetrate or pass through objects or barriers such as walls, furniture, etc.