With the ever expanding global economy, overhead cranes have become a critical tool for companies operating in the international marketplace, as well as domestic manufacturing and industrial operations. These large and powerful cranes regularly lift and transport hundreds of tons of cargo, equipment and other loads on a daily basis. Despite their vital role, there is inherent risk involved in their use for both equipment and personnel, which must be mitigated in order to ensure long term successful operations. Many standards now exist with the aim to improve crane safety, especially in the United States.

Crane Warning Lights

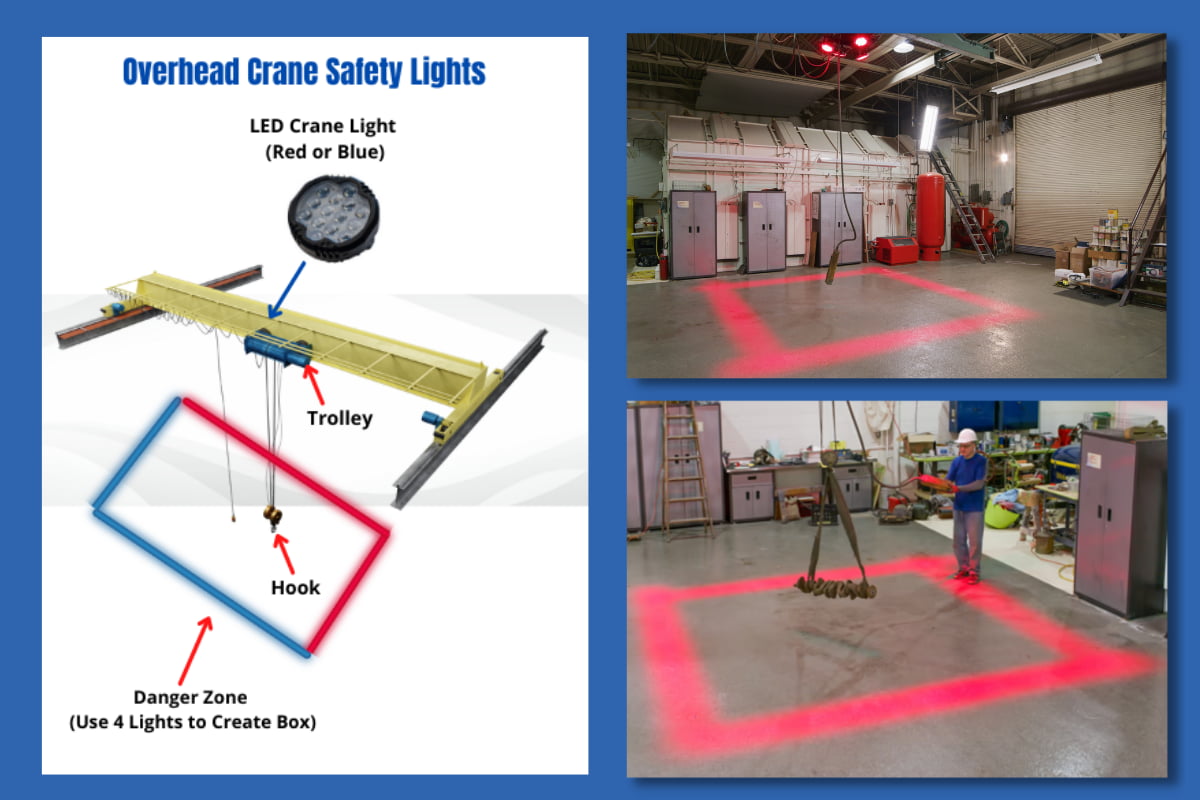

Crane warning lights are by far the most popular of crane warning systems used today. Also known as crane safety lights, they provide excellent safety warning zones for all crane operators and personnel in the immediate vicinity of the crane. One of the best features of these lights is their relatively straightforward set up, as they simply are mounted to a crane head or trolley carriage and remain fixed in position afterwards. Since crane lights almost universally use LED technology, they require minimal maintenance, with no regular parts replacement needed.

Other Types of Warning Systems

In addition to crane warning lights, there are several other key warning methods used to manage the risk surrounding overhead cranes. These warning systems are composed of multiple systems that either function in concert with each other or independently. While some of these types of systems have been in existence for generations, there are new technologies that have appeared in recent years that increase crane safety and awareness to previously unimaginable levels.

One of the popular systems used for crane warning systems are Load Moment Indicators (LMI), which are electronic devices that measure several factors such as hydraulic pressure in crane cylinders and the angle at which boom arms are positioned to determine the weight of a load. These devices then transmit this data to a display used by crane operators and other personnel to understand exactly what is happening with the crane at all times.

Another commonly used warning system for crane operations are proximity warning devices. These systems use proximity sensors mounted on the crane head or trolley carriage to create a zone around the load that will trigger an alarm if it is breached. This accomplishes a similar goal as crane safety lights, but will actively alert personnel to danger instead of relying on individuals noticing lighted safety zones on the ground. These systems are often used in conjunction with safety lighting to provide both an active and passive mode of safety warnings.

General purpose audible alarms are an additional form of warning systems for overhead cranes. These alarms are normally set up to activate when the crane begins an operation, such as picking up or moving a load. They also commonly activate when the crane begins its movement on the trolley or is pivoting on its axis, such as when it is moving a load from one area to another. While less effective than the previously mentioned warning systems, audible alarms are very easy to set up and when combined with other warning systems provide an extra layer of awareness and safety to operators, employees and any other individual in the vicinity of a crane operation.