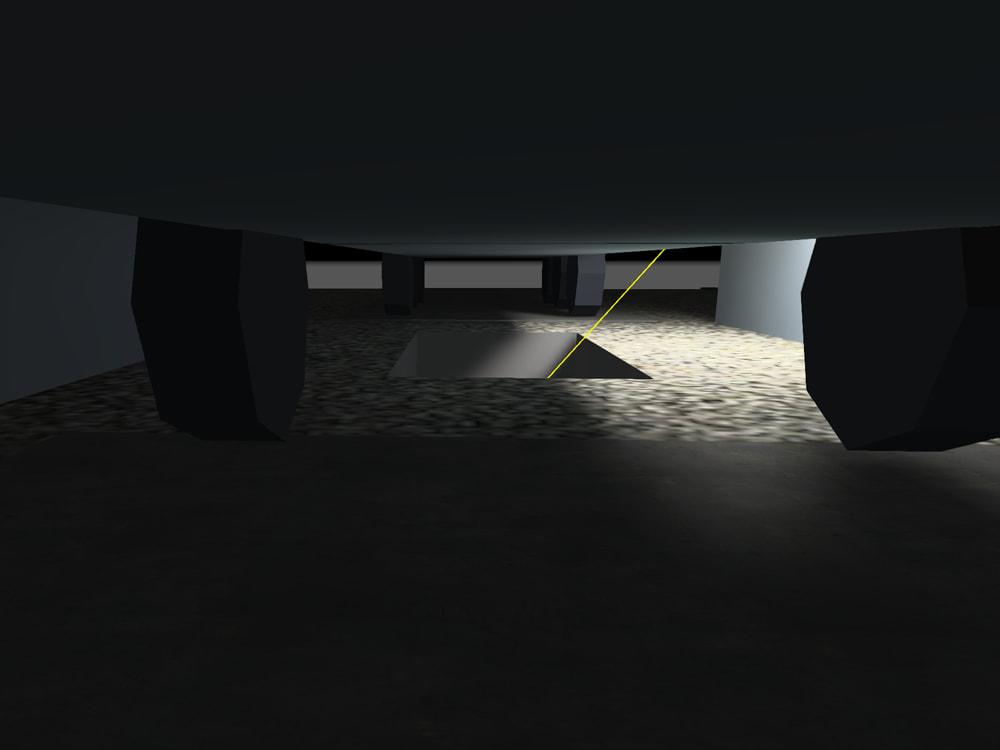

This case study delves into the unique lighting challenges faced by a grain silo, specifically within its 16×20 unloading area. To facilitate efficient unloading processes, the client sought a specialized lighting solution that would clearly illuminate the area and ensure trucks are correctly positioned over the unloading port. Given the nuances of their operations and the potential hazards associated with grain dust, they needed a light that would seamlessly integrate safety with functionality.

After detailed evaluation, our team suggested the use of our 60 watt LED square explosion-proof lights. These fixtures come with Class II Division II Group G certifications, making them particularly suited for environments like grain silos where combustible dust might be present. With a strategic mounting height at 7 ft elevation, these lights are positioned to offer optimal illumination, ensuring that workers can easily discern if a truck is aligned correctly over the unloading port.

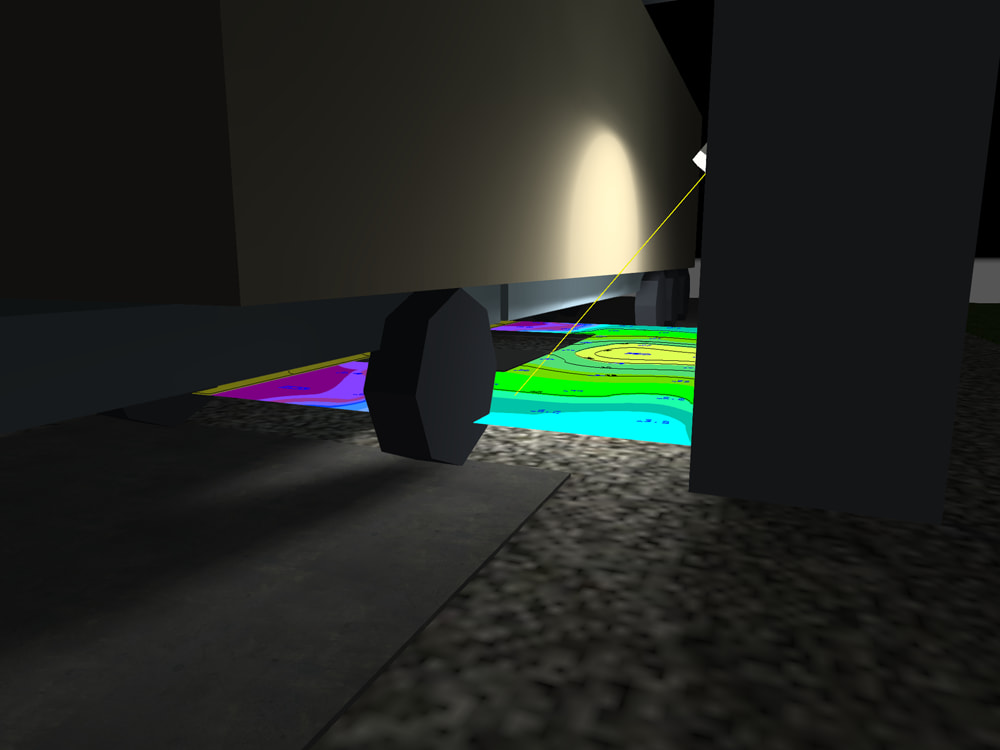

Grain Silo Lighting Design

The lighting design prioritized uniform and effective illumination. Utilizing the 60W LED Square Explosion Proof Lights, the unloading area experienced a maximum of 68.8 foot-candles, with an average of 20.1 foot-candles on the driver’s side. This meticulous placement and choice of lighting ensure that the entire unloading area is well-lit, facilitating safer and more efficient operations.