Grain Processing & Storage Lighting

Lighting for Grain Processing & Storage Areas

Grain handling facilities are common throughout the world, playing an important part in the global food supply chain. These facilities handle everything from the processing of grain to the long term storage of grain. One of the biggest hurdles these facilities face is the fact that grain dust can be easily ignited, resulting in accidental explosions and fires.

When this occurs, the results can be catastrophic, leading to loss of life and unnecessary expense to farm owners. Because lighting is the most common source of accidental ignition across the board, it has been a source of ever increasing focus for those in charge of facility safety.

Our Class 1 Division 2 explosion proof lighting systems are ideal for this grain processing and handling facilities and play a big part in agricultural workplace safety.

Explosion Proof Jelly Jar Lights

Mount on flat surfaces inside grain silos or on other areas within the facility

Explosion Proof Linear Lights

Suspended lights for use inside the grain processing facility or storage area for ceilings under 20 feet high

Explosion Proof High Bays

Use for high ceilings 15 feet or higher inside the grain processing facility or storage area

Grain Lighting Information

The most common source of accidental ignition of grain dust is sparks from exposed electrical components. Because of this, electrical systems within grain handling facilities are shielded from dust and vapor ingress, eliminating a possible source of ignition. The largest section of a facility's electrical system is the lighting system, which not only physically comprises the majority of the electrical components but also generates considerable amounts of heat. Because of this, lighting used in facilities handling grain must be sealed from the outside environment to prevent accidental fires and explosions.

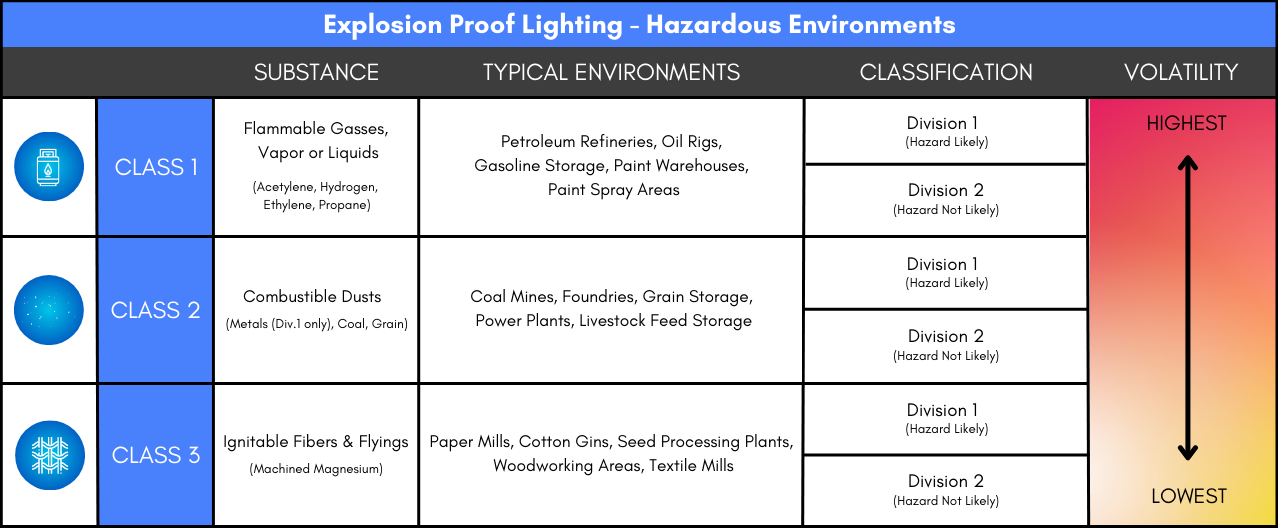

There are several industry standards for explosion proof lighting that are commonly used in grain storage facilities. The main standard used for grain processing and handling is Class 1 Division 2, which is governed by the standard UL 844 and the National Electric Code (NEC) article 501. This standard covers everything from explosive gasses to flammable liquids and combustible dust.

Lighting for Grain Processing Plants

Grain processing plants generate a large amount of combustible organic dust, through the processing of wheat, barley and other crops. Combined with high foot traffic and a number of moving machines, it is critical that these plants are equipped with explosion proof lighting systems. Proper lighting for these facilities allows for optimal illumination and visibility for workers, making their work safer and more efficient.

Lighting for Grain Storage Areas

Grain storage areas require similar types of lighting fixtures, due to similar hazards involving grain dust. However, the biggest difference is that grain storage covers a much larger area, which necessitates different lighting fixtures with a broader beam pattern. The most common explosion proof lighting fixtures for grain storage areas are linear and high bay lighting, as they are typically mounted high above in order to provide clearance for varying levels of grain within the storage silos.

Grain Bin Lighting

Grain bin lighting is an essential but often overlooked aspect of grain storage and management. Adequate lighting is critical for safety and efficient operation, especially when grain bins are accessed during early mornings or late evenings. Traditional incandescent or fluorescent lights have been used in the past, but these options are less efficient and durable.

Nowadays, LED lighting is increasingly becoming the go-to choice for grain bins. LEDs offer superior energy efficiency, longer lifespan, and better luminosity, making it easier to inspect the quality of grain and to spot any issues such as mold growth or infestation. Moreover, explosion-proof LED lights are often recommended for grain bins, given the potentially hazardous environment where dust and fumes may be present.

LED Explosion proof lights are designed to operate safely in such conditions, reducing the risk of fire or explosion as well as offering a safe, durable, and energy-efficient solution for grain bin lighting.

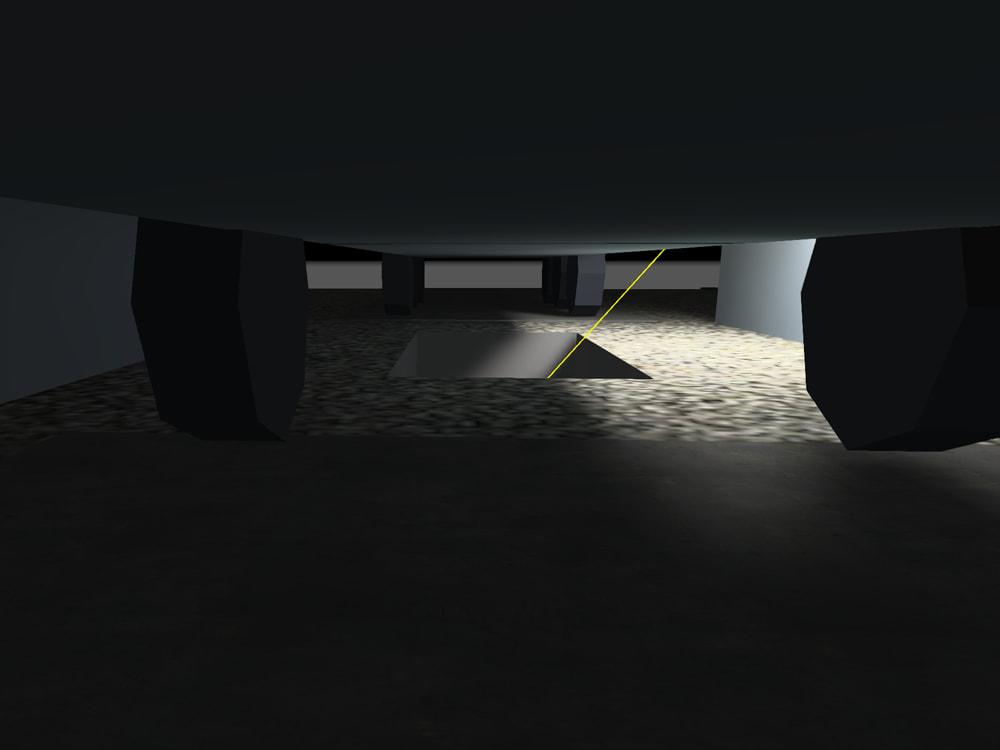

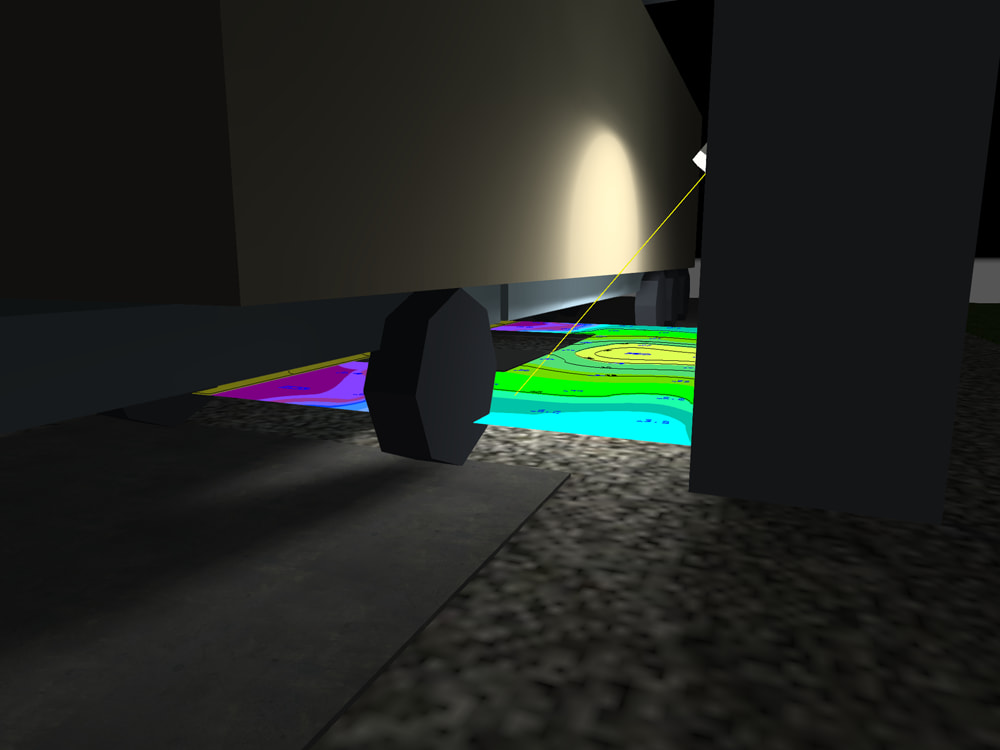

Grain Silo Lighting Design

The lighting design prioritized uniform and effective illumination. Utilizing the 60W LED Square Explosion Proof Lights, the unloading area experienced a maximum of 68.8 foot-candles, with an average of 20.1 foot-candles on the driver's side. This meticulous placement and choice of lighting ensure that the entire unloading area is well-lit, facilitating safer and more efficient operations.