Paint Booth Lighting

LED Lights for Paint/Powder/Blast Booths

We carry a variety of explosion proof LED paint booth lights including C1D1, C1D2, and other certifications required by various global regulatory bodies for hazardous areas. Our lighting fixtures are stocked in the U.S, ready to ship, and can ship internationally if needed.

Paint Booth Lighting Information

In a paint booth, proper lighting is paramount for both safety and precision work. Many paint booths operate in environments that can be flammable due to the presence of paint vapors and solvents. In these spaces, it's essential to use explosion-proof lighting fixtures. These fixtures are engineered to contain any sparks or explosions that might occur within them, ensuring the overall safety of the booth and preventing larger, hazardous incidents.

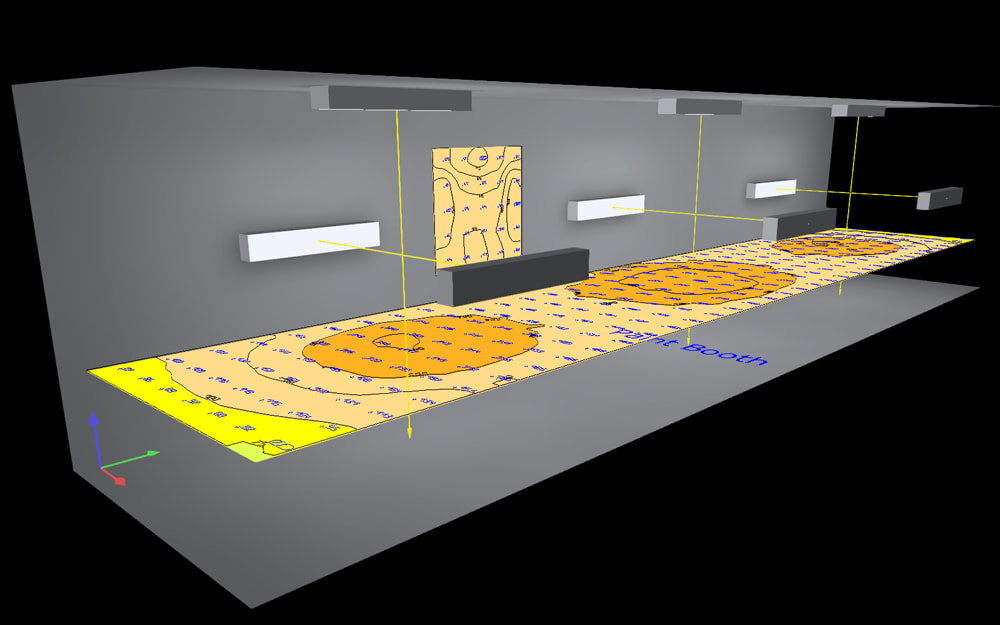

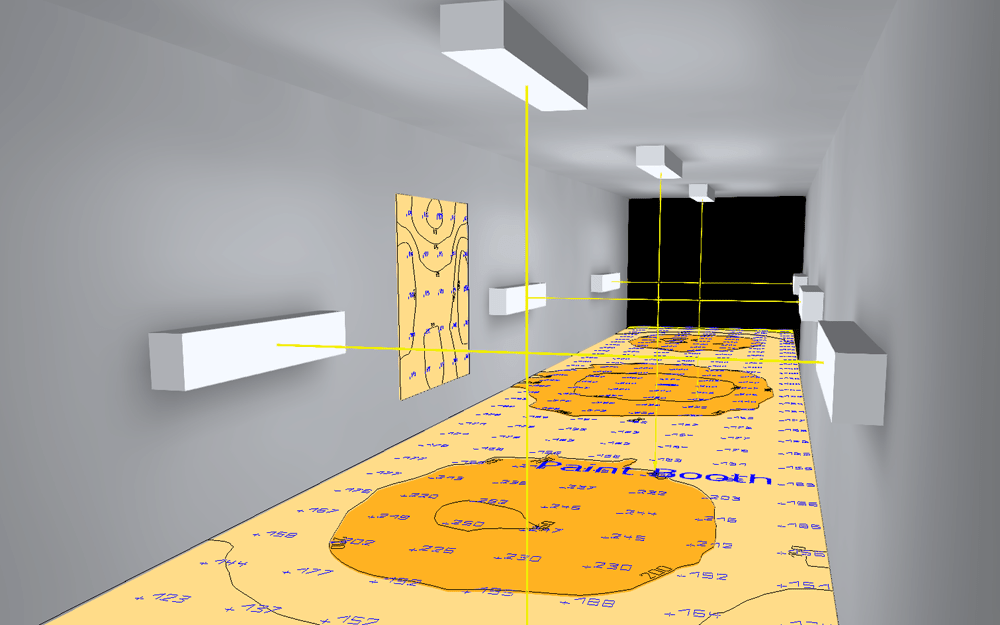

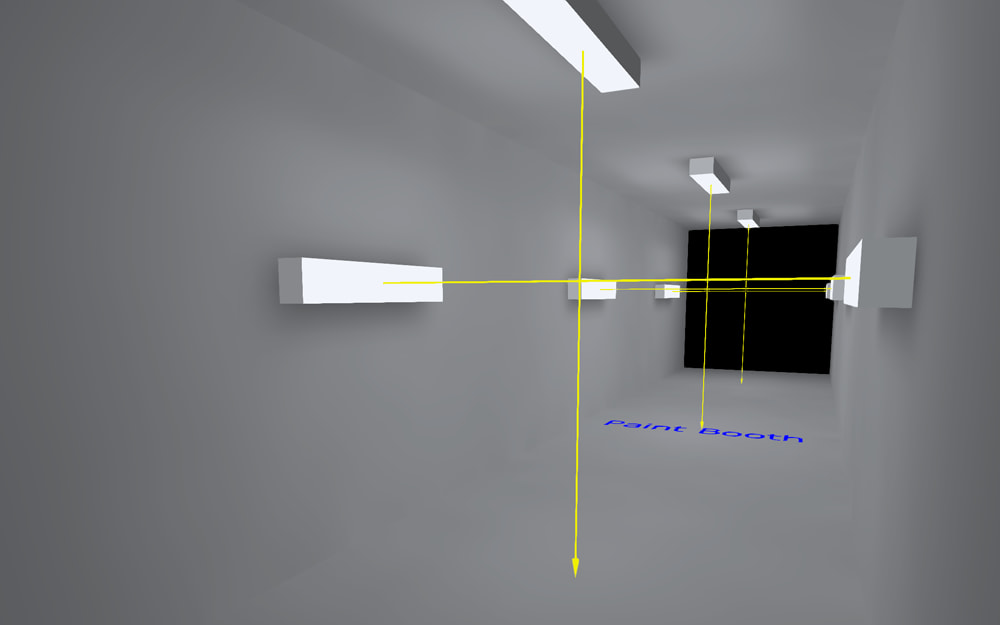

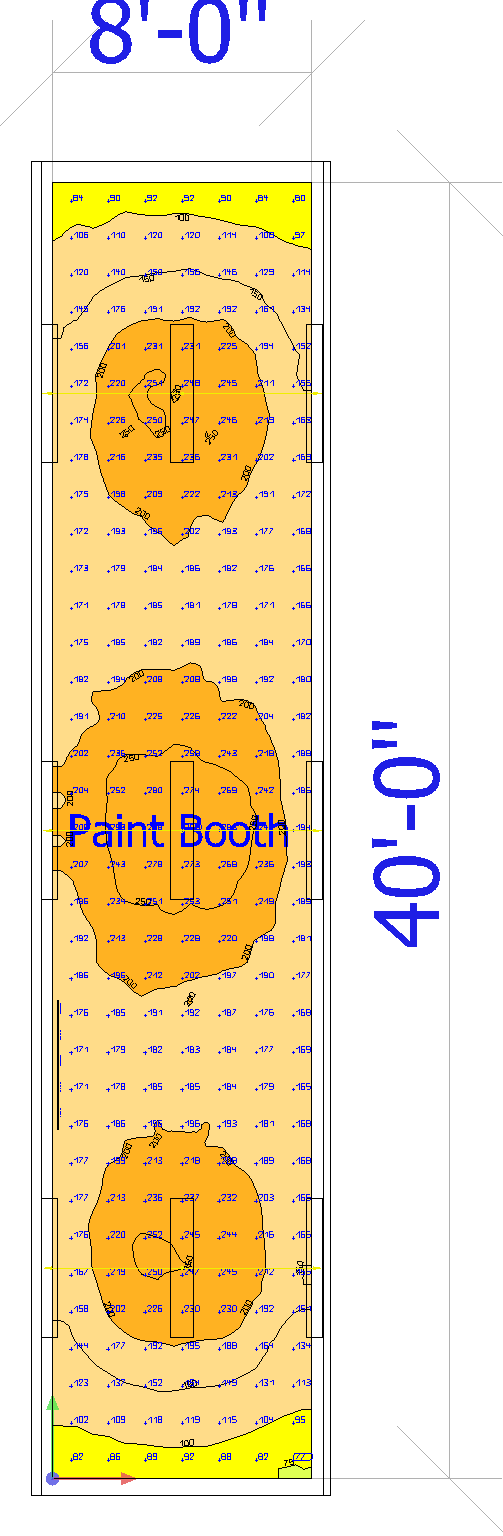

Paint Booth Lighting Design

Here’s an example of a 3D paint booth lighting photometric design conducted by our professional lighting engineers. In this example nine 60W LED Explosion Proof 1x4 Vapor Proof Lights were used on a 40x8 foot paint booth with 9 foot ceilings. The fixtures were mounted on the wall and provided a maximum of 290 foot candles with a uniformity of 1.22-3.96.

Paint Booth Dimensions: 40 feet Long, 8 feet Wide, 9 Feet High

Fixture Type: 60W LED Explosion Proof 1x4 Vapor Proof Lights

Fixture Count: 9 PCS

Fixture Certifications: Class I Division 2 Group A, B, C, D

Foot Candles (Floor): 186fc, Max 290fc, Min 73 fc (at both ends)

Foot Candles (Side): 155fc, Max 170fc, Min 139 fc

Illumination Uniformity: 3.96 (floor) 1.22 (side)

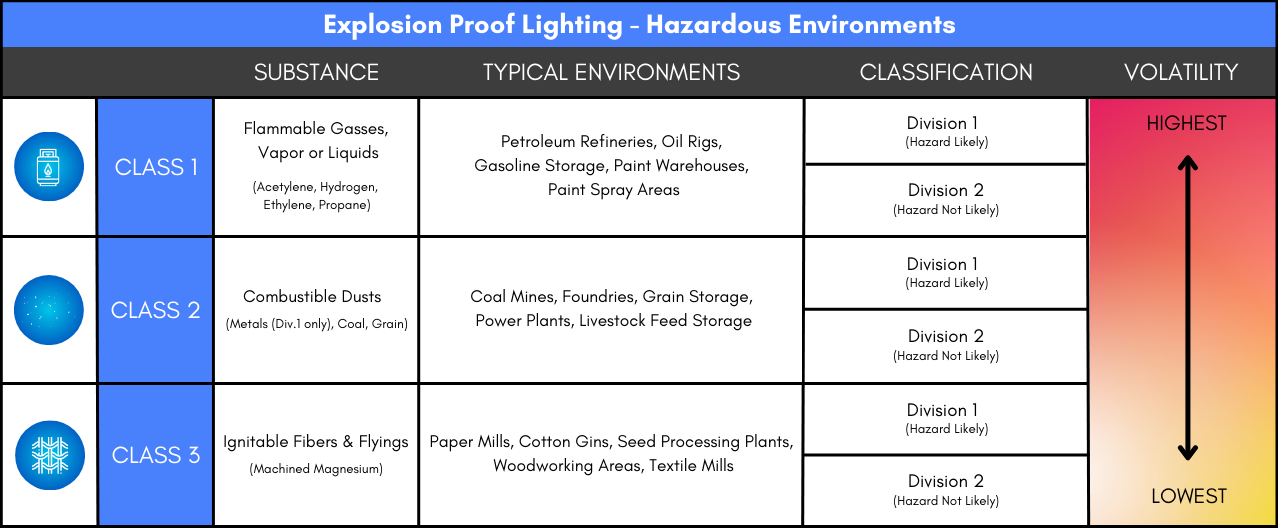

Lighting Classes and Divisions

The National Electric Code (NEC)/National Fire Protection Association 70 (NFPA) Article 500 lists three Hazardous (Classified) Locations which indicates the nature and degree of a hazard existing in a particular location. Article 500 provides a general description for Class 1. Article 501 provides specifics.

- A Class 1 Locations “are those in which flammable gasses, flammable liquid-produced vapors or combustible liquid-produced vapors, are or may be present in the air in quantities sufficient to produce explosive or ignitable mixtures”.

The two Division designations defines the chance a hazardous material is present in an ignitable concentration. Article 500 provides a general description for Division 1 and 2.

- A Division 1 location is one in which:

- “Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors can exit under normal operating conditions”.

- “Ignitable concentrations of such flammable gases, flammable liquid-produced vapors or, combustible liquids above their flash points may exist frequently because of repair or maintenance operations or because of leakage,” or

- “Breakdown or faulty operation of equipment or processes might release ignitable concentrations of flammable gases, flammable liquid-produced vapor, or combustible liquid-produced vapors and might also cause simultaneous failure of electrical equipment in such a way as to directly cause the electrical equipment to become a source of ignition”.

- Division 2 location is one in which:

- “Volatile flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors are handled, processed, or used, but in which the liquids, vapors, or gases will normally be confined within closed containers or closed systems from which they can escape only in case of accidental rupture or breakdown of such containers or system or in case of abnormal operation of equipment” or

- “Where combustible dust accumulations are present but are normally insufficient to interfere with the normal operation of electrical equipment or other apparatus, but could as a result of infrequent malfunctioning of handling or processing equipment become suspended in the air,” or

- “Combustible dust accumulations on, in, or in the vicinity of the electrical equipment could be sufficient to interfere with the safe dissipation of heat from electrical equipment or could be ignitable by abnormal operation of failure of electrical equipment”.

The four NFPA Article 500 Class I Group Designations represents a specific subclassification of the nature of the hazard categorized by a common character; the four groups are listed in the below table:

| Group Designation | Hazard Description (Type) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Group A | Acetylene | ||||||||||||||||||

| Group B | Flammable gas, liquid-produced vapor, combustible liquid-produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value less than or equal to 0.45 mm or minimum igniting current (MIC) ratio less than or equal to 0.40. Typical material is hydrogen. | ||||||||||||||||||

| Group C | Flammable gas, liquid-produced vapor, combustible liquid-produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value greater than 0.45 mm and less than or equal to 0.75 mm, or minimum igniting current (MIC) ratio greater than 0.40 and less than or equal to 0.80. Typical material is Ethylene. | ||||||||||||||||||

| Group D | Flammable gas, liquid-produced vapor, combustible liquid-produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value greater than 0.75 mm, or minimum igniting current (MIC) ratio greater than 0.80. Typical material is Propane. | ||||||||||||||||||