Paper Mill Lighting Information

In a paper mill, proper lighting is crucial for both safety and streamlined operations. Many paper mills operate in environments that can be humid and might have the presence of combustible dust. In these settings, it's vital to use moisture-resistant and explosion-proof lighting fixtures. These fixtures are crafted to handle the mill's unique conditions, ensuring the overall safety of the facility and reducing the risk of potential fire hazards related to dust ignition.

LED Lighting Systems for Pulp Processing

In the unique and challenging setting of pulp processing, where safety and reliability are paramount, explosion-proof LED lighting systems provide an essential solution. These environments, characterized by high humidity, fluctuating temperatures, and the potential presence of flammable dust and vapors, demand lighting that can withstand such extreme conditions without compromising safety.

Explosion-proof LED lights are designed to operate safely in these potentially hazardous areas, ensuring that any internal electrical malfunctions do not ignite the surrounding atmosphere. Their rugged construction makes them resistant to moisture, corrosion, and physical impact, a necessity in the harsh conditions of pulp processing.

The superior illumination quality of LEDs enhances visibility in operational areas, contributing to increased accuracy and safety in daily tasks. Moreover, the energy efficiency of these LED lights not only reduces operational costs but also aligns with the industry's growing focus on sustainable and environmentally responsible practices. By integrating explosion-proof LED lighting, pulp processing facilities can significantly elevate their safety standards while achieving greater energy efficiency and operational effectiveness.

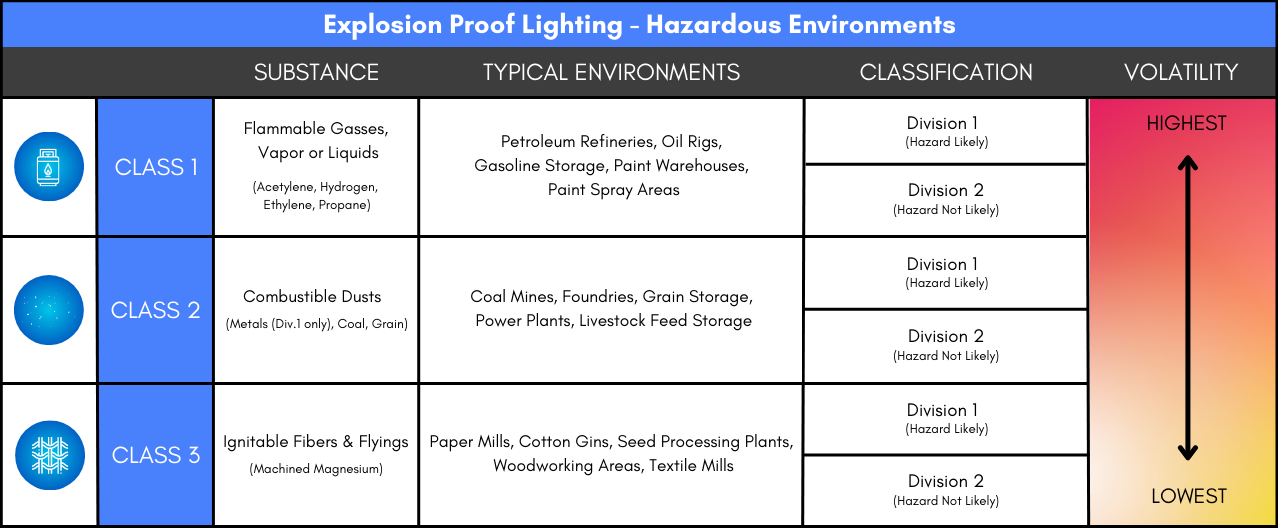

Lighting Classes and Divisions

The National Electric Code (NEC)/National Fire Protection Association 70 (NFPA) Article 500 lists three Hazardous (Classified) Locations which indicates the nature and degree of a hazard existing in a particular location. Article 500 provides a general description for Class 1. Article 501 provides specifics.

- A Class 1 Locations “are those in which flammable gasses, flammable liquid-produced vapors or combustible liquid-produced vapors, are or may be present in the air in quantities sufficient to produce explosive or ignitable mixtures”.

The two Division designations defines the chance a hazardous material is present in an ignitable concentration. Article 500 provides a general description for Division 1 and 2.

- A Division 1 location is one in which:

- “Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors can exit under normal operating conditions”.

- “Ignitable concentrations of such flammable gases, flammable liquid-produced vapors or, combustible liquids above their flash points may exist frequently because of repair or maintenance operations or because of leakage,” or

- “Breakdown or faulty operation of equipment or processes might release ignitable concentrations of flammable gases, flammable liquid-produced vapor, or combustible liquid-produced vapors and might also cause simultaneous failure of electrical equipment in such a way as to directly cause the electrical equipment to become a source of ignition”.