LED Lights for Barns and High Ceilings

When it comes to indoor pole barn lighting, it’s important to use the right type of fixture. For example, if you need highly focused lighting in a pole barn workshop, consider using UFO style lights to ensure proper safety and visibility.

On the other hand, if you have a larger pole barn used for storage, consider using linear style lights which produce a larger rectangular floor pattern of lighting.

Our experts can work with you to craft a lighting plan that’s both ideal as well as cost-effective for whatever your lighting needs and preferences are.

Pole Barn Lighting Layout

One of the more common barn lighting projects we undertake is pole barns. These types of barns are big outdoor buildings that are used for storage or as workshops. These commercial facilities require various types of low bay and high bay fixtures to ensure proper illumination throughout the work or storage space.

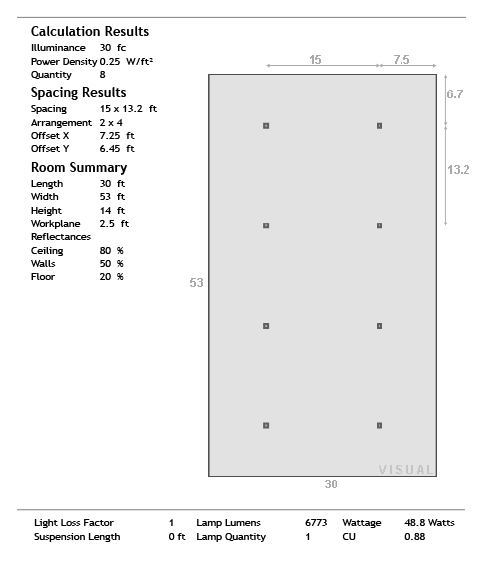

Here’s a photometric lighting example of a 30 ft wide x 53 ft pole barn with a ceiling height of 14 feet.

40x60 Pole Barn Lighting

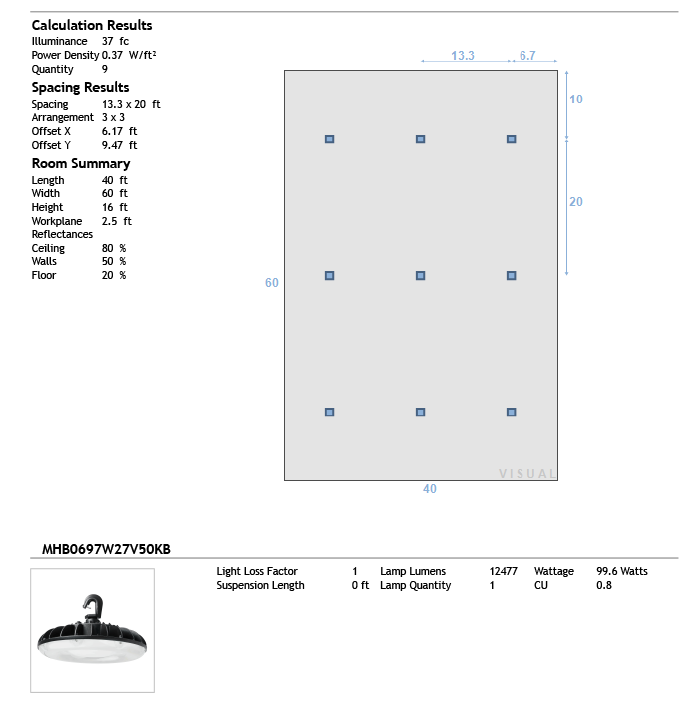

40x60 is one of the more common sizes/dimensions for these facilities. Here’s an example of a 40x60 pole barn lighting layout with a 16 foot ceiling that was designed by our lighting experts. These numbers were calculated to achieve between 30-40 foot candles which is what we advise for most pole barns.

30x40 Pole Barn Lighting

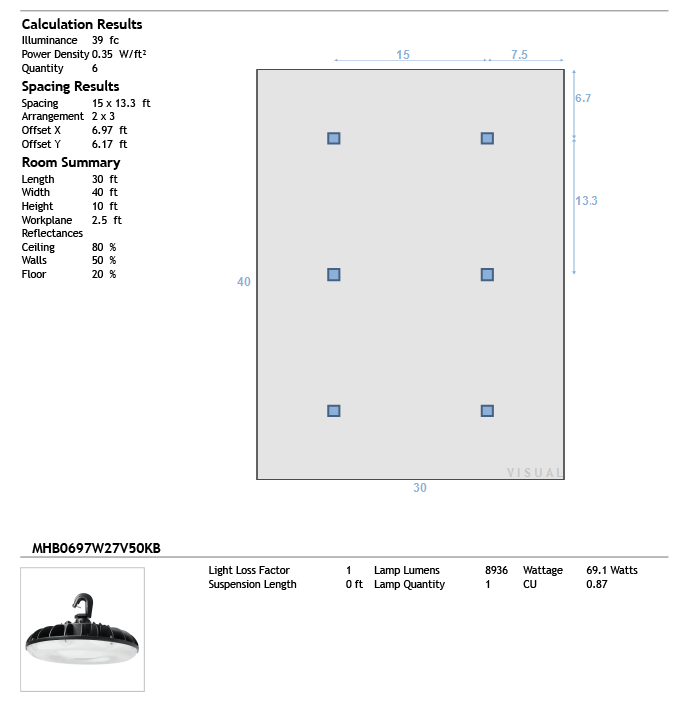

30x40 is also a common pole barn size. The layout below showcases a 30x40 pole barn lighting layout with a 10 foot ceiling put together by our LED lighting experts. These numbers were calculated to achieve between 30-40 foot candles which is what we advise for most pole barns.

Pole Barn Exterior Lighting

Lighting on the exterior of a pole barn is equally important in order to ensure proper outdoor illumination and security. We carry a selection of high quality LED wall packs and barn security lighting fixtures.

Benefits of LED Lights

As mentioned previously, one of the primary benefits of LED lighting is its dramatically improved energy efficiency. For most users upgrading from traditional lighting technologies, they see efficiency improvements of up to 70% once they make the switch. This is game changing, especially for large agricultural operations that may be utilizing dozens if not hundreds of fixtures at once.

In addition to this, LED lights also do not require any regular maintenance as you would find with traditional lighting fixtures. This saves not only countless labor hours and facility downtime, but also saves in annual parts costs. The effects this has on the bottom line of a business should not be underestimated, again especially for large operations.

On top of the improved efficiency and reduced operating costs, these lights also produce a significantly higher quality of light compared to traditional lighting. LED lighting has a noticeably higher lighting accuracy than HID or sodium lamps. This is quantified using the Color Rendering Index (CRI) which measures a light's ability to replicate natural sunlight on a scale running up to 100. LED lights are typically in the 80 to 90 CRI range, which is about 10-20 points higher than traditional lights. This has a noticeable effect on worker efficiency as well as improvements in safety.

LED Barn Lighting Fixtures

There are many different types and styles of fixtures used in barns today. The fixtures selected depend on numerous factors such as environmental conditions as well as the particular lighting requirements for that specific application. Below is a list of the most commonly used lighting fixtures for barns.

UFO High Bays - By far the most commonly used type of light in barns throughout the country, this compact fixture is round in shape and produces a significant lumen output for its size. Chosen primarily for their ease of installation and output to size ratio, UFO high bay fixtures are the closest to a one size fits all solution for any barn facility.

Linear High Bays - Similar in purpose to UFO high bays, these lights are designed for applications specifically requiring a linear beam output instead of a more traditional round beam. Popular for work areas such as horseshoe stations and workshops, linear high bays are versatile and easy to install using chains or cables affixed to the ceiling.

High Powered High Bays - These are the largest and most powerful overhead lighting fixtures on the market. Round in shape, these lights produce an exceptionally strong beam that can illuminate from any height encountered in a building. For barn applications, high powered high bay lights are usually used in very large commercial agricultural applications such as storage facilities.

Vapor Tight Fixtures - Linear in shape and sealed from the elements, vapor tight fixtures are ideal for areas which require weather resistant, cost effective fixtures. These fixtures are intended to be mounted at lower heights, such as on entryways, overhangs and atop workbenches.

Low Bay Lights - These linear fixtures look similar to linear high bay lights, however their beam pattern and lumen output are better suited for lower mounting heights. Due to their ability to hold up to a half a dozen LED tubes, low bay lights are extremely effective for areas that do not require weather resistance but instead need significant lighting capabilities.

Common Pole Barn Lighting Questions

Q. What is the best lighting for a pole barn?

The best lighting for pole barns is going to depend on several factors such as the size of your facility as well as ceiling height. For instance, if you want highly focused lighting from the ceiling, UFO style high bays are a great option. On the other hand, if you want broader rectangular shaped illumination for a larger area, linear style high bay lights are the way to go. There’s also specialized barn security lighting fixtures for barn exteriors.

Q. How do you wire a pole barn for lighting?

Sometimes we get electrical wiring questions such as how to wire a pole barn for lighting. For this application, we advise using an electrician for safety and to ensure the wiring is done correctly. With that said, if you’re going to attempt to ‘DIY’ the project, use conduit clamps and wood screws to attach the conduit to the poles inside the facility. You can also use a hacksaw to saw the conduit to the correct size. Use lock nuts at the end of the conduit and insert it into the boxes in order to attach it to circuit breakers and outlets. Again, these are general recommendations, and it’s advised to hire an electrician for this type of wiring.

Q. How many lights do you install in a 30x30x10 pole barn?

In order to adequately illuminate a 30x30 pole barn with 10 foot ceilings, we recommend 60-70 watt LED UFO high bay lights with a lumen output of 8,900-9,000.