LED Linear High Bay Lights Overview

The LED linear high bay lights we offer are durable, energy-efficient, and meet the lighting needs for commercial and industrial facilities.

Watts - Our LED UFO high bays range from 50W up to 400W.

Lumens - Our LED UFO high bays range from 6,900lm - 52,000lm.

Color Temperature (Kevin) - We offer 3000K, 4000K, and 5000K LED UFO high bays including specialized fixtures with adjustable color temperature (CCT).

Fixture Size - We offer LED high bays in sizes of, 1x2, 1x4, 2x1, 2x2.

What is An LED Linear High Bay Light

Linear LED high bay lights are high powered square or rectangular shaped lighting fixtures that are designed to provide broad illumination from high ceilings that covers the area below. These fixtures derive their name from the straight linear beam pattern of the light projected from a long rectangular shaped fixture. This design makes linear LED high bay lights a popular lighting option for aisleways as well as commercial and industrial facilities with large floor spaces.

Linear high bays differ from UFO high bay lights in that they project a broader beam of light in a square or rectangular shaped pattern which make them a more ideal lighting option if your goal is to broadly illuminate a large area from a high ceiling point.

Linear High Bay Sizes

Linear high bay lights come in various sizes to accommodate different industrial and commercial settings. Each size is typically selected based on the specific lighting needs and the dimensions of the space to be illuminated. Here are some of the most commonly used linear high bay fixture sizes:

1x4 Linear High Bay Lights - These are long and narrow, making them ideal for lighting narrow aisles or corridors within a warehouse or factory setting. The 1x4 size allows for focused light distribution along a straight path, minimizing wasted light and enhancing visibility in targeted areas.

2x2 Linear High Bay Lights - Compact and versatile, 2x2 linear high bays provide a square coverage that is suitable for a variety of spaces, including smaller rooms or areas that require a more concentrated light spread. They are often used in smaller industrial spaces or can be spaced more closely together in larger areas for increased light uniformity.

2x4 Linear High Bay Lights - This is one of the most common sizes for linear high bay lights, offering a good balance between size and coverage area. The 2x4 fixtures are perfect for general purpose lighting in a wide range of commercial and industrial settings, such as manufacturing plants, warehouses, and large retail environments. They provide ample light with a broad distribution, making them efficient for areas requiring substantial illumination.

Linear High Bay Accessories

Wire-Guard Cages - Protective covers that enclose the light fixture, preventing damage from external impacts. They are especially useful in high-traffic or rugged environments like warehouses, workshops, and manufacturing facilities, safeguarding the fixtures from accidental bumps or hits.

Motion Sensors - These sensors detect movement and automatically turn the lights on or off, helping to conserve energy. Motion sensors are particularly beneficial in spaces that aren't constantly in use, such as storage rooms or infrequently traveled hallways.

Dimmers - Allow for adjustable light intensity, providing flexibility in setting the right ambiance or brightness level. Dimming controls can be particularly useful in spaces where different activities require varied lighting levels, such as in retail environments, offices, or production areas.

Emergency Battery Backup - Provides power to the fixture during electrical outages, ensuring uninterrupted light for up to 90 minutes or more. This accessory is crucial for safety in facilities like hospitals, schools, or emergency shelters.

Hanging Kits - These include chains, hooks, or other mounting hardware to suspend linear high bay lights from ceilings at the desired height. They are essential for installations in high-ceiling spaces, ensuring that the light is positioned optimally for even distribution.

Linking Brackets - Allow multiple linear high bay lights to be connected in a seamless row, providing continuous illumination across longer areas. These brackets are useful in spaces with large coverage needs, such as aisles in warehouses or supermarkets.

Remote Controls - Enable easy adjustments to settings such as dimming or motion sensor sensitivity from a distance. This accessory is useful in hard-to-reach spaces or for centralized control of multiple fixtures.

Reflectors and Diffusers - Reflectors focus the light output in a specific direction, enhancing brightness in a targeted area. Diffusers, on the other hand, help spread the light evenly, reducing glare and creating a softer lighting effect, making them suitable for areas like offices or retail spaces.

Linear LED High Bay Fixture Spacing

For Linear LED High Bay Lights, fixture spacing also crucially depends on the specific dimensions of the space and the ceiling height, similar to UFO high bays but with a focus on their elongated spread of light. Linear high bays, due to their shape, are typically better suited for illuminating long, narrow spaces like warehouse aisles or large open areas where rows of lighting are necessary. Their design ensures a more uniform light distribution along the length of the fixture, which can affect spacing requirements.

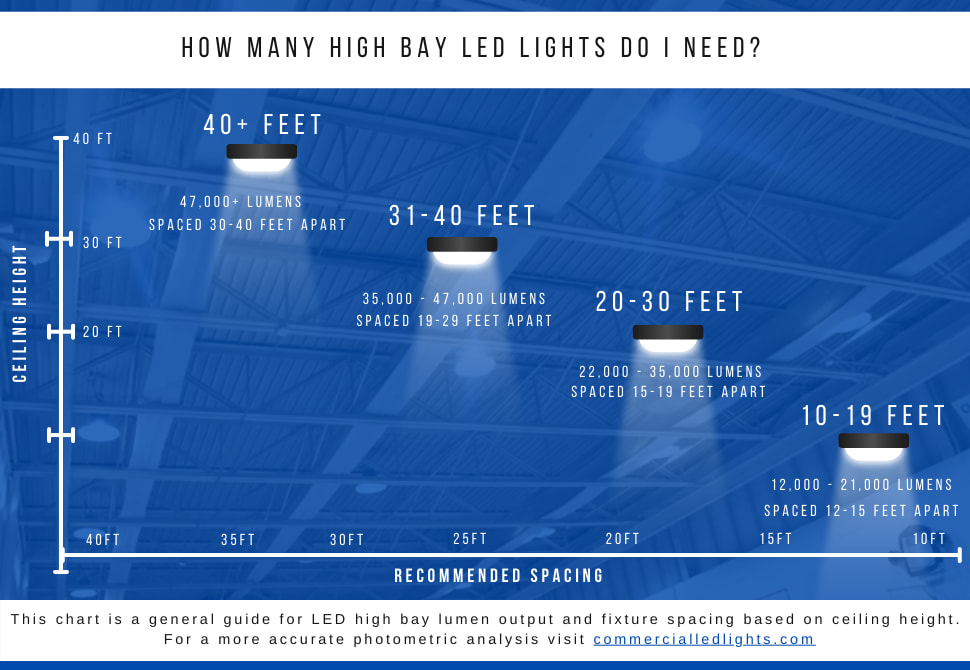

Here’s a general guideline for spacing linear LED high bay fixtures based on ceiling height:

- 10-foot ceiling: Space the fixtures approximately 10-12 feet apart. This closer spacing helps avoid shadows and ensures consistent light coverage for lower ceiling applications.

- 20-foot ceiling: Fixtures should be spaced about 15-20 feet apart. The higher the ceiling, the wider the spread of light, so spacing can be extended slightly compared to lower ceilings.

- 30-foot ceiling: Spacing can range from 20-25 feet apart. The higher positioning allows for a broad distribution of light, suitable for larger industrial spaces.

- 40-foot ceiling: Fixtures might be spaced around 25-35 feet apart. At this height, the linear high bays are effective in covering wide areas with sufficient light intensity.

| Ceiling Height | Recommended Spacing |

|---|---|

| 10-foot ceiling | 10-12 feet apart |

| 20-foot ceiling | 15-20 feet apart |

| 30-foot ceiling | 20-25 feet apart |

| 40-foot ceiling | 25-35 feet apart |

It's important to consider other factors such as the wattage and lumens of the specific linear high bay model, the layout of the space, and the type of activities performed under the lighting. A lighting designer or engineer can provide more tailored specifications based on detailed analysis of the environment.

Linear High Bay Lens Type

Linear high bay lights can be equipped with various types of lenses to modify the distribution of light to better suit specific needs within different environments. Here’s an overview of common lens types used in linear high bay lighting fixtures:

Clear Lenses: These lenses provide maximum brightness and light penetration, making them ideal for areas where high visibility is crucial. The clear lens does not diffuse the light, allowing for a more concentrated and direct illumination.

Frosted Lenses: Frosted lenses help to diffuse the light, reducing glare and providing a softer light distribution. This makes them suitable for environments where a more even light spread is needed, such as in assembly areas, retail spaces, or places where people work for extended periods under artificial lighting.

Prismatic Lenses: These lenses are designed to both diffuse and direct light more efficiently. Prismatic lenses can help control brightness and reduce glare, which is particularly useful in workplaces to enhance visual comfort and productivity. Polycarbonate Lenses: Known for their durability and impact resistance, polycarbonate lenses are suitable for environments where the light fixtures may be exposed to physical impacts or harsh conditions. These lenses can come in clear or frosted forms.

Acrylic Lenses: Similar to polycarbonate in terms of light diffusing capabilities, acrylic lenses are less impact-resistant but offer superior clarity and are more cost-effective. They are commonly used in indoor applications where the risk of impact is minimal.

How Many LED Linear High Bay Lights Do I Need?

In order to determine the number of high bay lights required to illuminate the space, you’ll need to determine several factors including,

- Ceiling height

- Dimensions of the space

- Facility usage

- Environmental factors

For example if you have a ceiling height that’s under 11 feet, we generally recommend using a high bay fixture that’s between 50-100 watts and 9,000-12,000 lumens.

As ceiling height increases, higher lumen output and wattage will be required to adequately illuminate the space.

Linear High Bay Fixture Spacing

When it comes to fixture spacing for Linear LED high bay lights, it’s important to consider the size of the lighting space as well as ceiling height.

Generally speaking, for ceiling heights that range from 15 to 40 feet high, you’ll want to space the fixtures as far apart as the ceiling height; for instance, fixtures mounted at 40 feet should be spaced around 40 feet apart, while fixtures mounted at 30 feet should be spaced about 30 feet apart.

Linear High Bay Applications

Linear LED high bay lights are ideal for commercial and industrial areas with ceiling heights ranging from 15-35 feet high. Common practical applications include but are not limited to the following,

Linear LED High Bay Light Uses

Linear high bay lights are the preferred choice of warehouses, workshops and industrial facilities throughout the world. In recent years, LED’s have come to dominate the high bay market due to their many advantages over traditional HID fixtures. LED Linear high bays are a popular choice for business owners and building managers looking for lighting solutions that offer reduced energy consumption, lower maintenance and longer lifespan.

Linear High Bay Lighting Guide

Warehouse, shop and industrial faculty owners and operators are always looking for ways to reduce operating costs in order to improve their business’s bottom line. One of the areas that always stands to be improved is lighting, which is generally considered a fixed cost. Historically, high bay lighting has always had a large impact on annual budgets. This is due to the high lumen requirements of facilities with high ceilings. For those looking to significantly reduce this large section of their operating budget, linear LED high bays have become the dominant choice. This is due to their dramatically increased energy efficiency, lower maintenance requirements and long lifespan.

Linear LED high bay lights are similar in purpose to UFO LED high bays in that they illuminate areas with elevated ceilings such as warehouses, workshops and industrial facilities. Usually these facilities have ceilings over 20’ tall, some even as tall as 40’. Lights mounted this high up must produce a large amount of light, spread evenly over a large area. Since these lights draw significantly more power than regular lights mounted on lower ceilings, their efficiency is paramount to avoid unnecessary energy expenditures.

The biggest difference between Linear high bays and their UFO counterparts is the way in which the light is distributed. UFO LED high bay lights distribute their light in an even round pattern, whereas linear high bay lights distribute their light in a rectangular pattern. This can have advantages in certain situations where illumination of walkways and long narrow areas is desired. Linear high bay lights can also be used in situations requiring intense light density, such as over a workspace or high traffic area.

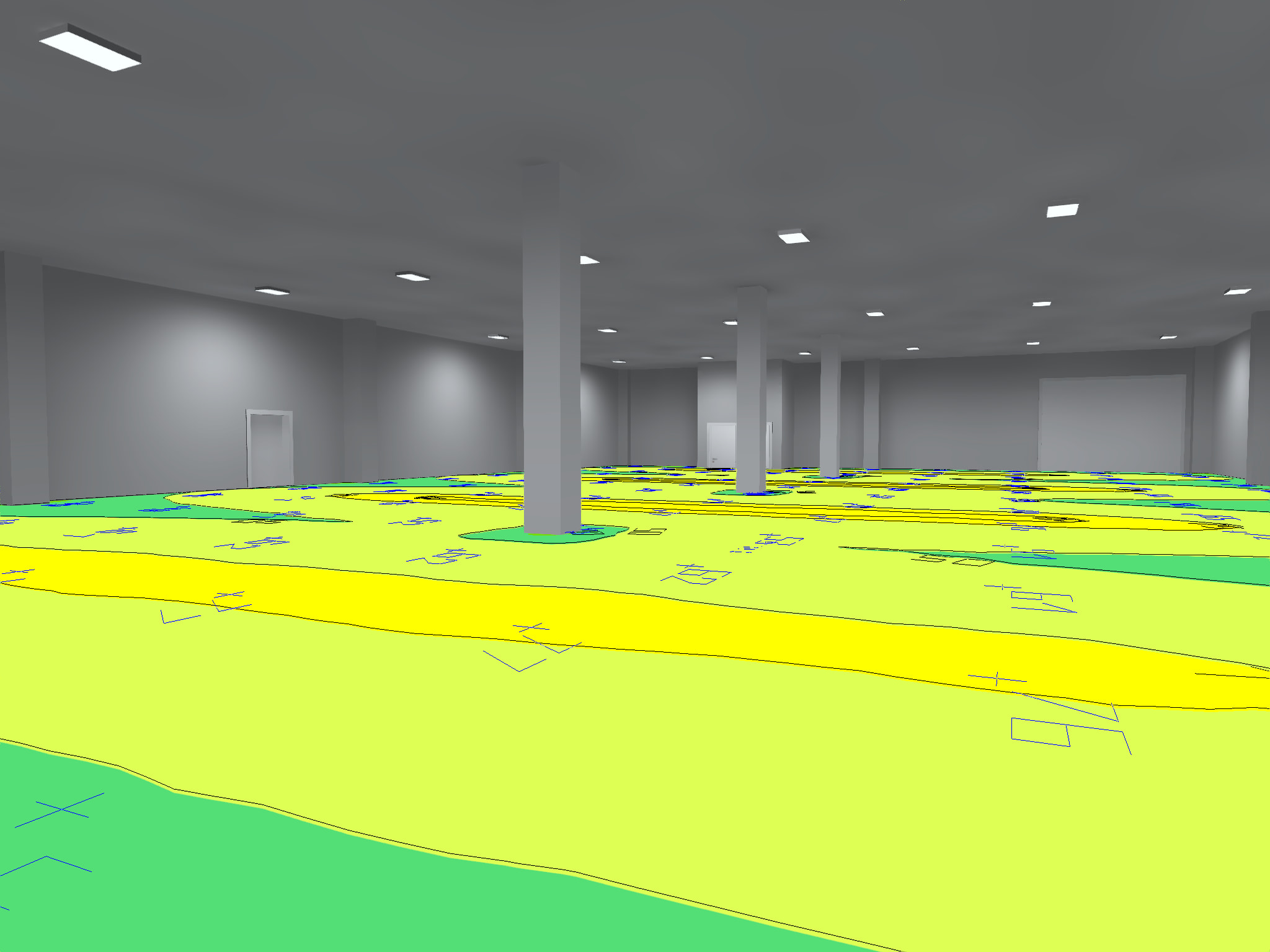

Professional Linear High Bay Lighting Design

Here’s an example of an LED Linear High Bay lighting design constructed by our professional lighting engineers. In this example, a retail owner specifically asked for a linear high bay lighting design for a 50x75x12ft for his new basement retail storage area. The design consisted of a 4x6 Grid (24 fixtures) with 90W Linear High Bay Lights. This modeled an average 58.6 footcandles (fc) with a 82.2 fc maximum and 17.5 fc minimum,

Storage Room Dimensions: 50 x 75 x 12ft

Fixture Type: 90W Linear High Bay Lights

Fixture Count: 24

Fixture Certifications: UL, DLC

Average footcandles: 58.6 fc

Maximum footcandles: 82.2 fc

Minimum footcandles: 17.5 fc

Types of LED Linear High Bays

We offer several types of linear LED high bay lights for any warehouse application. The Packard Series features premium Samsung LED technology, producing a high quality of light. They are constructed with a shatterproof housing and are made of robust components - ensuring a long and trouble free lifespan. All of these lights feature DLC, UL, IP20, IP40, LM79 qualifications and come with a five year warranty. The Packard Series offers two primary types which we will describe in detail.

Packard Series 2x2 - These come in both 100W and 150W power ranges, producing 16,350 and 24,750 lumens respectively. For sizing purposes, the 100W version is designed to replace a 300W traditional high bay light and the 150W is designed to replace a 400W traditional high bay light. Both are 2’ long fixtures.

Packard Series 2x4 - This light comes only in a 200W version and produces a staggering 33,000 lumens. This light is designed to replace a 750W traditional high bay light and is a 4’ long fixture.

Frequently Asked Questions

Q. What are Linear high bays?

Linear high bay lights are long rectangular lighting fixtures that are used in buildings with tall ceilings. These ceilings usually are between 20’ and 40’ in height and therefore require a high powered light in order to properly illuminate the ground below. These fixtures are typically hung from cables, chains or another type of apparatus.

Q. Where are Linear high bays used?

Linear high bays are often used in place of the traditional round UFO style lights when a rectangular light pattern is desired. They are also used in applications requiring extra levels of illumination for safety and efficiency reasons. Popular uses include areas such as workspaces, walkways and high traffic areas.

Q. Why should you use LED Linear high bays?

Using LED lights yield many advantages over traditional bulbs such as Halogens or Incandescents. This is especially true for commercial and industrial needs such as high bay ceilings. For example, LED bulbs are more durable, energy-efficient, and produce less harmful toxins when compared to other types of bulbs. In other words, switching to LEDs can save costs and promote safety throughout a facility. Linear high bays are a highly versatile lighting fixture; LED tubes are used in conjunction with this fixture to provide high quality energy-efficient illumination throughout any warehouse or commercial facility.

The California Lighting Technology Center discusses the impact of using LEDs for high bay lighting in a 2015 report. According to the report,

“By 2020, advanced products and best practices will transform the California lighting market to deliver a 60 to 80% reduction in statewide electrical lighting energy consumption from 2010 levels.” (UC Davis California Lighting Technology Center, 2015, Lighting Technology Overview)