Warehouse Lighting

LED Warehouse Lights

Warehouse lighting fixtures must be designed to withstand harsh conditions while providing consistent, accurate illumination over large areas. Our warehouse lights are DLC Premium Verified and protected against moisture and dust. We work with electrical contractors and project managers to design lighting layouts that maximize illumination quality while minimizing cost.

LED High Bays (Linear)

Use for warehouse walkways, rectangular floor spaces, entryways, loading dock interiors, aisleways, and assembly lines

LED High Bays (UFO)

Use for general area lighting inside warehouses and other industrial facilities requiring a broad but highly bright light pattern.

LED Vapor Tight/Wet Area Lights

Use for car washes, fabrication shops, cold storage, walk in coolers, and areas exposed to water vapor.

Browse Selection

Browse Selection

LED Strip/Shop Lights

Use in storage areas, workshops, inspection stations, and other low ceiling areas within the warehouse

Browse Selection

Browse Selection

Hazardous Area Lighting (C1D1 & C1D2)

Use in areas exposed to hazardous materials such as flammable gasses, combustible dust, or ignitable fibers

LED Low Bay Lights

Use for general area lighting inside the facility with lower ceilings, generally around, 15 feet or less

Browse Selection

Browse Selection

LED Corn Lamps

Use for retrofitting existing fluorescent and metal halide fixtures inside a warehouse with modern LED light bulbs

LED Crane/Forklift Lights

Use for safety lighting around overhead crane loads, forklifts, and other hazardous industrial machinery to increase precision and protect workers

LED Lighting in Warehouses

One of the most appealing benefits of LED lighting is its dramatically increased efficiency compared to traditional types of lighting such as fluorescent, metal halides, sodium lamps, CFL bulbs and HIDs. Warehouses that have switched over to LED lighting have seen as much as an 84% ROI in their lighting operations. This dramatic improvement in ROI is not only due to a 40% increase in efficiency, but also the lifespan of LED bulbs being over three times that of traditional lighting.

Here’s a summary below of a warehouse lighting case study where a metal industry supplier with several warehouses replaced fluorescent T5 lamps with Straits Lighting Apollo LED UFO high bays. These high bays are one of the many quality solutions offered at our store.

Current Annual Lighting Cost

LED Lighting Cost

LED Retrofit Cost

Annual LED Savings

Financial Summary

High Bay Warehouse Lighting

One of the most common types of lighting used in warehouses are high bay lights. These fixtures are ideally designed to cast illumination from high ceilings. These ceilings typically range from 20-40 feet up from the floor.

The benefit of using high bay lights is that these fixtures are designed to operate smoothly in harsh conditions without the need for maintenance. These lights also have the energy and lumen output to ensure adequate illumination throughout large commercial or industrial facilities.

here are two primary categories of high bay warehouse lighting.

Linear High Bay Lights - Square or rectangular shaped fixtures designed for warehouse walkways, rectangular floor spaces, isleways, and assembly areas.

UFO High Bay Lights - Round shaped lights for general area lighting inside warehouses that require a broad but highly bright light pattern.

Warehouse Lights with Motion Sensor

Many high bay lighting fixtures now feature motion sensor technology, either as an integrated unit or an optional add-on. This new feature has been increasing in popularity over the past decade, due to its effectiveness as well as ease of installation. In the past, multiple motion sensors would be required to be mounted throughout a facility to activate or deactivate lights, which would then independently cycle the power on and off to the lighting system.

With current motion sensor technology being integrated into the fixtures themselves, this eliminates the extra hassles and costs associated with setting up an independent motion sensor system. It also allows for more precise measurement of motion inside a room, which means only the lights in the immediate vicinity of individuals in the room will illuminate versus the entire room at once. This saves electricity and extends useful fixture life, saving a considerable amount of costs over the lifetime of the fixture.

Warehouse Foot Candles

The Illuminating Engineering Society (IES) has recommendations for warehouse illumination. This will depend on several factors, namely, the type and size of your facility. Here are some recommended foot candles (fc) for warehouses, workshops, and manufacturing facilities;

| Storage Warehouse Lighting | Footcandles |

|---|---|

| Inactive Warehouses | 5-10 fc |

| General Warehouse Aisles | 10-30 fc |

| Active Warehouse (Large Items) | 20 fc |

| Active Warehouse (Medium Items) | 20 fc |

| Active Warehouse (Small Items) | 30-60 fc |

| Active Warehouse (Fine Items) | 30-60 fc |

| Cold Storage / Refrigeration | 10-30 fc |

| Warehouse Dock Lighting | 5-20 fc |

| Receiving and Staging Area | 15-60 fc |

| Manufacturing Warehouse Lighting | Footcandles |

|---|---|

| Packaging and Labeling | 30 fc |

| Coarse Material Processing | 10 fc |

| Medium Material Processing | 30 fc |

| Fine Material Processing | 50-100 fc |

| Simple Assembly | 30 fc |

| Medium Assembly | 25-100 fc |

| Difficult Assembly | 100-200 fc |

| Complicated Assembly | 50-200 fc |

| Exacting Assembly and Inspection | 150-600 fc |

| Grain Processing | 70 fc |

| Food Processing | 70 fc |

| Workshop & Maintenance | 50 fc |

| Warehouse Parking Lot Lighting | Footcandles |

|---|---|

| Horizontal illuminance | 0.2 fc (minimum) |

| Vertical Illuminance | 0.1 fc (minimum) |

| Uniformity Ratio | 20:1 (maximum) |

| General Parking Lots | 2-5 fc |

| Parking Structures | 2-5 fc |

| Underground Parking Garages | 1 fc |

Warehouse Lighting Layout Design

Designing a warehouse lighting layout takes a fair amount of planning. One of the first steps is determining how high the ceiling is. You’ll also want to determine other dimensions of the room such as length, width, etc. With this information you can begin to determine the spacing of the lighting fixtures in order to see how many foot candles are required to properly illuminate the space below. Another important factor to consider is whether or not your lights will be exposed to conditions such as dust, water vapor etc.

Since determining these factors takes a great deal of planning and calculation, our lighting experts work with building managers and contractors and assist them by providing an professionally designed photometric lighting plan in order to determine the most efficient and cost-effective solution for their facility.

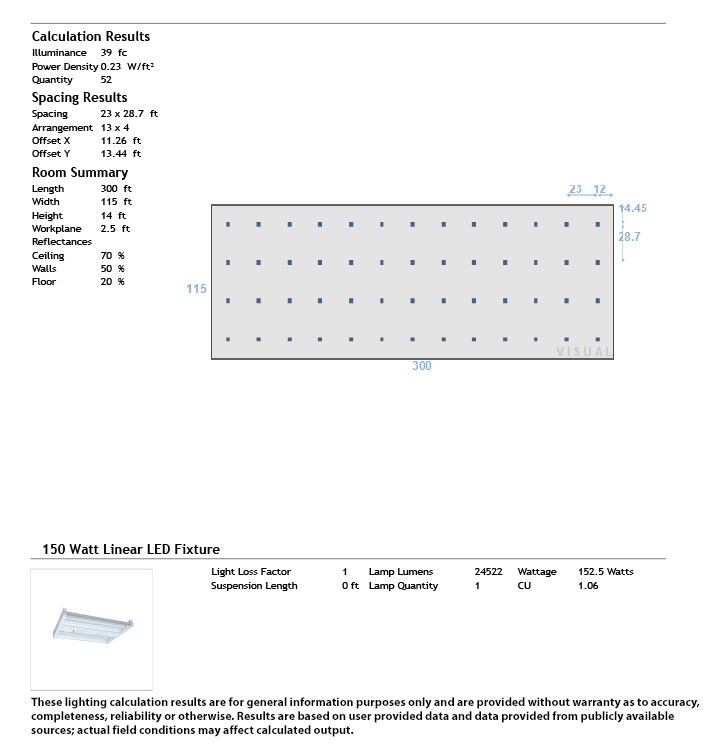

Here’s an example of a warehouse lighting project that our lighting experts provided for a facility manager. This plan strategically laid out 52 LED linear high bay lights for a warehouse with a 14 foot high ceiling.

As you can see this photometric design provides details such as recommended foot candles, fixture quantity, total lumen output, total wattage, etc.

Warehouse Lighting Recommendations by Ceiling Height

Choosing the most ideal lighting fixture will largely depend on the ceiling height within the facility. For example, large facilities with ceiling heights between 30-40 feet typically require round shaped UFO high bay lights due to their compact design and high lumen output. This design and energy output give them the ability to cast bright illumination with a wide beam angle from high areas.

On the other hand, smaller areas with ceiling heights of 15 feet or lower should typically use less powerful lights such as 4 foot LED strip lights. These shop lighting fixtures cast adequate illumination without expending excessive energy; they’re also light, occupy minimal space, and are sold at a highly affordable price point.

Here are general warehouse lighting guidelines based on ceiling height within the facility. Please note, these recommendations are very general, to obtain an accurate lighting plan, we recommend consulting with one of our lighting experts.

| Ceiling Height | Lumen Output | Ideal Fixture Spacing | Ideal Fixture Type |

|---|---|---|---|

| 15-20 feet | 10,000 - 22,000 | 10-15 feet | 50W UFO High Bays, 100-150W Linear High Bays |

| 20-25 feet | 22,000 - 32,000 | 15-25 feet | 220W UFO High Bays or 150W Linear High Bays |

| 25-30 feet | 32,000 - 35,000 | 15-30 feet | 230W UFO High Bays or 150W Linear High Bays |

| 40+ feet | 47,000 | 30-40 feet | 360W UFO High Bays |

About Our Warehouse Lighting Fixtures

Warehouse Lighting Recommendations by Location

Utility & Storage Rooms - Since these areas do not require intense light output, energy efficiency and minimal maintenance, lighter duty lights can be used. The most commonly used are linear style utility lighting, as well as replacement bulbs such as T8 LED tubes and corn lamps.

Warehouse Loading Dock Lighting - As high traffic areas, loading docks at warehouses necessitate substantial lighting in order to ensure safe and efficient work. The most commonly used on the indoor side of the dock are high bay fixtures, which produce exceptional lumen output. On the outdoor side, canopy lights, wall packs and floodlights are the best choice for weatherproof illumination.

Overhead Crane Safety - There are several specific light fixtures that are specifically designed for overhead cranes and machinery. Primarily, this includes linear crane lights and spotlight style crane lights. These lights create an exclusion safety zone below the load being carried by the crane head, alerting workers to the danger above.

Forklift Safety - As pieces of heavy mobile machinery, forklifts have the potential to cause serious injuries or even death when safety is neglected. Because most forklift accidents occur as a result of a lack of situational awareness, forklift safety strobe lighting is one of the most effective ways of reducing accidents. These lights use external drivers to power bright LED lights that provide a clear indication as to the location of forklifts.

Workshops - Due to the detailed nature of work performed in the average workshop, quality lighting is important. For this application, the most popular type of fixture used are typically low bay lights, thanks to their exceptional lumen output over a wide area. Linear shop lighting is often used to fill any gaps that higher powered low bay lighting may leave.

Cold Storage - Because these lights are exposed to condensation as a result of refrigeration, it is important that they are sealed from moisture. Vapor tight fixtures are the best choice for this application, as they are impervious to moisture as well as providing solid lumen output over a wide area.

Warehouse Exterior Walls - For building exteriors, the best solution for ensuring sufficient illumination are wall pack lights. These lights are sealed from the elements and virtually maintenance free throughout their long service life.

Warehouse Parking Lots - Parking lots have wide areas that need to be illuminated in order to ensure safety and security for users. For this application, floodlights are the top choice, as they provide intense illumination in a relatively compact package, and are easy to mount on poles or other exterior mounting surfaces.

LED Warehouse Lighting Questions

Q. How do you light a warehouse?

Warehouses require serious lighting systems in order to have proper illumination for both the efficiency of daily activities as well as safety for workers. These systems typically consist of UFO high bay style lights in order to provide sufficient foot candle levels at the ground, with linear high bay lighting being a popular choice for aisleways and other areas requiring a linear beam pattern. Typically, warehouse lighting systems will be designed as part of a photometric plan, with commercial quality fixtures to ensure long life and reduced maintenance.

Q. What is the difference between 4000k and 5000k lighting in warehouses?

Essentially, the difference between 4000K and 5000K is how close the color temp is to natural sunlight, or how “white” the light is. While these two color temps are very close, the 5000K has a whiter color that more accurately replicates sunlight, whereas the 4000K has a yellow hue that is softer on the eyes. Most warehouses use 5000K due to his inherently better visibility, however some choose to use 4000K due to it being slightly less harsh.

Q. What is the typical light level for a warehouse in the U.S?

This is largely dependent on the area of the warehouse being illuminated, however as a rule of thumb 30 foot candles is the most appropriate for general area lighting. Certain areas such as entryways and high traffic areas will usually have higher foot candle ratings of approximately 50 foot candles in order to ensure higher visibility to reduce the chance of accidents.

Q. What is better lighting for a warehouse fluorescent or LED?

Outside of highly specialized lighting used for laboratory work, LEDs are the superior choice in every conceivable application, including warehouse lighting. LED technology performs better in all measurable performance categories, including higher lumen output, longer life, reduced energy consumption, more environmentally friendly materials, and smaller packaging.

Fixture Safety and Performance Qualifications

Having an ideal lighting solution for warehouses will improve visibility within the facility while maximizing energy-efficiency. Not only does this save energy costs for a business, but also helps to reduce workplace accidents and improve productivity.

IP65 Rating - This is a rating given to enclosures that are designed to protect against low pressure water spray from all directions, in addition to condensation and moisture. This is the minimum rating needed for lighting fixtures used in outdoor applications.

DLC Premium - This is a classification for high performance luminaires and retrofit kits. The intent of this premium classification is to highlight products that achieve higher energy efficiency while simultaneously providing excellent quality light as well as controllability that exceeds the standard classification for DLC requirements.

IP40 Rating - This is an indoor only rating, which protects against objects larger than 1mm from touching the electrical components - such as tools and large wires. It does not provide protection against water spray, or high humidity environments. Typically seen on indoor commercial fixtures.

IP67 Rating - This is a waterproof rating given to enclosures and devices designed to be submerged underwater up to a meter deep for up to an half hour. It provides significantly better protection for outdoor lighting fixtures and also completely protects against dust or dirt ingress.

LM79 Rating - Fixtures carrying this rating are tested according to LM-79-08, which is a test method developed by the Illuminating Engineering Society of North America (IESNA). This defines the methodologies behind lab testing of solid state lighting, such as LEDs. Essentially, an LED light carrying an LM79 rating has passed an industry standard test to ensure its performance and longevity.

UL Listing - Short for Underwriters Laboratories, Inc., this is a certification for any electrical product that passes their safety standards. In the realm of lighting, bulbs and fixtures bearing a UL listing mark are guaranteed to be free from deficits in electrical engineering, resulting in a safer product.

Many reputable safety organizations recognize the importance of having proper illumination in industrial facilities. For example, the Teamsters provide information on the importance of lighting in warehouses on their website. According to the Teamsters:

“Workers at a warehouse need to spot oncoming vehicles, pedestrians, slippery floors and other hazards in time to prevent injuries and accidents. Areas of the warehouse that require lighting include the loading dock, shipping and receiving areas, open storage areas, and rack storage…” (Teamsters Safety & Health Facts, 2004, Lighting (Illumination) in Warehouses)

Here at commercialledlights.com each of our fixtures contain the necessary safety and performance qualifications such as DLC Premium and IP65. We sell industrial quality lighting fixtures for maximum illumination as well as safety lighting solutions to prevent accidents around heavy machinery.

Color Rendering Index (CRI)

LED lighting offers a significantly better quality of light compared to traditional lighting. LED lighting has a very high CRI (Color Rendering Index), which means that the light it produces is more accurate and real. CRI runs on a scale of 0-100, with 100 being natural sunlight. LED lighting typically has a CRI of 90, sometimes even more - whereas traditional lighting rarely has a CRI beyond 80. This is actually quite a significant difference, which can be clearly noticed to the naked eye in side-by-side comparisons.

In addition to the higher CRI, LED lighting also offers an approximately 40% increase in usable light compared to traditional lighting. This is due to the way in which the light is focused. Traditional lighting generally produces light in a 360° pattern, requiring the use of a reflector to redirect light in the correct direction.

This results in a significant efficiency loss which is not present in LED lighting. Because LEDs can only produce 180° patterns, they do not require reflectors to redirect light as all the light is going in the correct direction to begin with. This increase in usable light combined with the exceptionally high CRI of LED lighting increases safety for warehouse workers by more accurately illuminating their workspace and creating less strain on their eyes.