Explosion Proof Wall Lights

Explosion-proof wall pack lights are specifically designed for use in hazardous areas where there is a high risk of accidental fires or explosions. These environments often contain flammable gasses, vapors, dust, or liquids that can potentially ignite and cause explosions.

One example of an ideal environment for explosion-proof wall pack lights is a paint storage facility or chemical warehouse. These locations are well-suited for explosion-proof wall pack installations because they require specialized Class 1 Div 2 lighting and typically have exterior walls where such lighting can be mounted.

Our explosion-proof Class 1 Div 2 LED wall pack lights are meticulously engineered to provide robust and reliable illumination. They are designed with the necessary durability and sufficient lumen output to ensure high-quality lighting throughout hazardous environments, enhancing safety and visibility along pathways and perimeter areas.

Explosion Proof Wall Pack Applications

Explosion proof lights are used in hazardous areas that have a high risk of accidental fires or explosions. These environments usually have some level of flammable gasses, vapors, dust or liquids that are present that can potentially ignite and create explosions. Common applications include but are not limited to the following:

- Chemical Processing

- Chemical Storage

- Grain Processing / Storage

- Power Plant Lighting

- Oil & Gas Lighting

- Oil Rig Lighting

- Petrochemical Lighting

- Mine Lighting

- Marine Environments

- Engine Room Lighting

- Paper Mill Lighting

- Distilleries/Alcohol Production

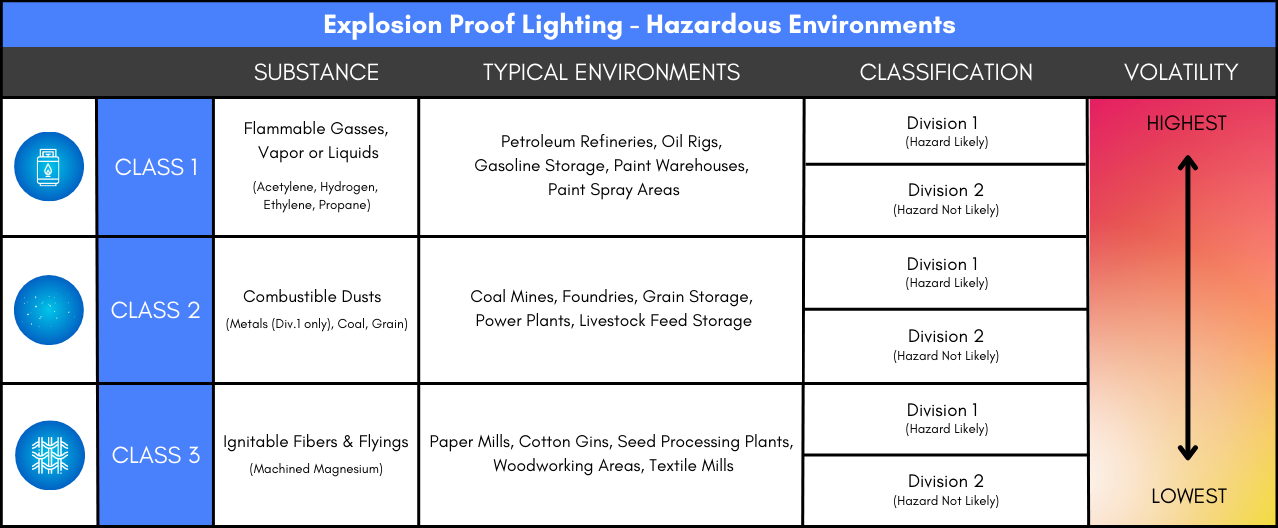

Class, Division and Group Information

The National Electric Code (NEC)/National Fire Protection Association 70 (NFPA) Article 500 defines three Hazardous (Classified) Locations which indicates the nature and degree of a hazard existing in a particular location. Per Article 500.5 section (B):

- Class 1 Location is one in which:

- “Flammable gasses, flammable liquid-produced vapors or combustible liquid-produced vapors are or may be present in the air in quantities sufficient to produce explosive or ignitable mixtures”.

The two Division designations defines the probability a hazardous material is present in an ignitable concentration. Per Article 500.5 section (B) (2):

- Division 2 location is one in which:

- “Volatile flammable gases, flammable liquid-produced vapors, or combustible liquid-produced vapors are handled, processed, or used, but in which the liquids, vapors, or gases will normally be confined within closed containers or closed systems from which they can escape only in case of accidental rupture or breakdown of such containers or system or in case of abnormal operation of equipment” or

- “Where combustible dust accumulations are present but are normally insufficient to interfere with the normal operation of electrical equipment or other apparatus, but could as a result of infrequent malfunctioning of handling or processing equipment become suspended in the air,” or

- “Combustible dust accumulations on, in, or in the vicinity of the electrical equipment could be sufficient to interfere with the safe dissipation of heat from electrical equipment or could be ignitable by abnormal operation of failure of electrical equipment”.

The four Class I Group Designations represents a specific subclassification of the nature of the hazard categorized by a common character; the four groups defined in NFPA 500.6 are listed in the below table:

| Group Designation | Hazard Description (Type) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Group A | Acetylene | ||||||||||||||||||

| Group B | Flammable gas, liquid-produced vapor, combustible liquid-produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value less than or equal to 0.45 mm or minimum igniting current (MIC) ratio less than or equal to 0.40. Typical material is hydrogen. | ||||||||||||||||||

| Group C | Flammable gas, liquid-produced vapor, combustible liquid-produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value greater than 0.45 mm and less than or equal to 0.75 mm, or minimum igniting current (MIC) ratio greater than 0.40 and less than or equal to 0.80. Typical material is Ethylene. | ||||||||||||||||||

| Group D | Flammable gas, liquid-produced vapor, combustible liquid-produced vapor mixed with air that may burn or explode, having either a maximum experimental safe gap (MESG) value greater than 0.75 mm, or minimum igniting current (MIC) ratio greater than 0.80. Typical material is Propane. | ||||||||||||||||||

Explosion Proof LED Wall Pack Mounting

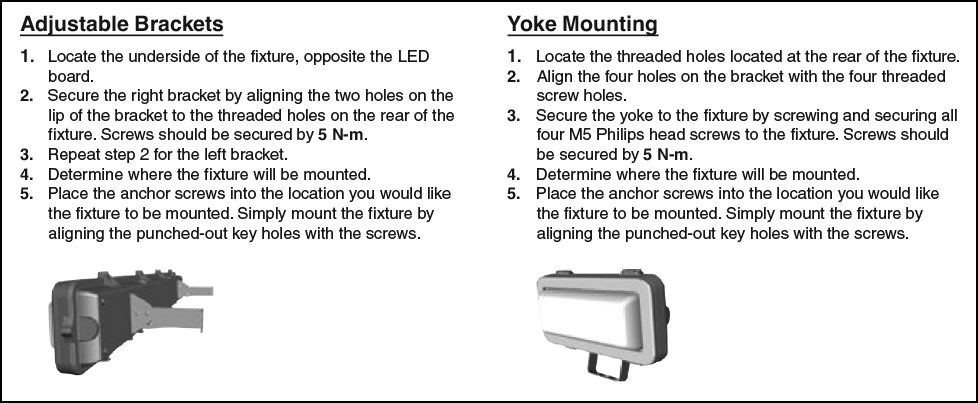

Adjustable Bracket Mounting - The adjustable bracket mounting option for LED wall packs is designed for flexibility and ease of installation. This mounting system features brackets that can be securely attached to the rear of the fixture using screws, which are then tightened to ensure stability. The brackets themselves are adjustable, allowing for precise positioning of the light fixture to achieve optimal lighting angles and coverage. This type of mounting is particularly beneficial in areas where directional lighting is needed, as it allows the installer to adjust the angle of the light post-installation to accommodate specific lighting requirements.

Yoke Mounting - Yoke mounting offers a robust and secure installation method for LED wall packs, ideal for both indoor and outdoor settings. This mounting style involves a yoke bracket with multiple holes that align with corresponding threaded holes at the rear of the fixture. Once aligned, the fixture is secured using four M5 Phillips head screws, providing a strong and stable attachment. Yoke mounting is particularly useful for locations that require a durable mount capable of withstanding environmental stresses such as wind or vibration, ensuring the fixture remains in the desired position for optimal illumination.